玻璃钢化炉用熔融石英陶瓷辊

✦出色的热稳定性: 用高级融合二氧化硅陶瓷材料设计, 这些滚筒表现出非凡的热稳定性, 使他们能够承受在玻璃回火炉中遇到的极端温度,而不会变形或退化.

✦低热膨胀: 较低的热膨胀系数, 这些滚筒即使在快速温度变化下也保持其形状和尺寸, 确保对回火过程的精确控制并最大程度地减少钢化玻璃产品中失真的风险.

✦均匀的热分布: 滚筒的设计目, 确保一致的结果并最大程度地减少可能导致机械性能不均的热梯度.

✦耐化学性: 抗熔融玻璃和清洁剂的腐蚀性, 这些滚筒即使在恶劣的玻璃制造环境中也保持其性能和完整性, 确保长期耐用性和可靠性.

✦可自定义的设计: 可自定义设计可容纳各种玻璃尺寸, 厚度, 和炉配置, 这些滚筒提供量身定制的解决方案,以满足玻璃回火应用的特定要求, 增强制造过程中的灵活性和多功能性.

产品图像

产品证书

-

描述

-

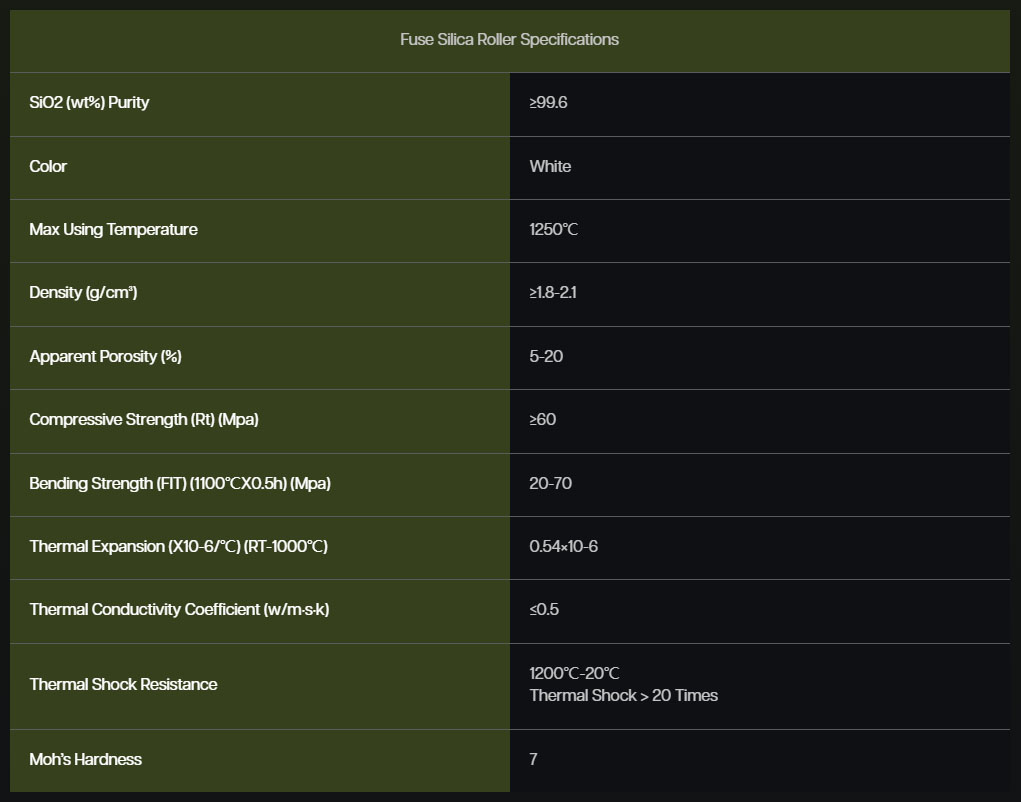

规格

-

FQA

融合的二氧化硅陶瓷辊是玻璃回火炉中的关键组件, 在回火过程中,它在支撑和运输玻璃中起着至关重要的作用. 这些滚筒经过设计以承受高温和玻璃回火过程中涉及的快速变化.

具有精确的尺寸和光滑的表面饰面, 融合的二氧化硅陶瓷辊为炉子内的玻璃移动提供了一个稳定的低摩擦平台. 它可以使玻璃的平稳运输, 在整个回火过程中确保加热和冷却. 它提供了极好的支撑和抵抗力的磨损和磨损, 促进其寿命和耐用性.

应用领域: 熔融石英陶瓷辊

玻璃回火炉: 用于加热和快速冷却玻璃产品, 这些滚筒在确保均匀的回火效果并增强钢化玻璃产品的机械强度和安全性方面起着至关重要的作用.

建筑玻璃: 用于制作建筑应用的钢化玻璃面板的生产, 例如建筑外墙, 视窗, 门, 和分区, 安全性和耐用性至关重要的地方.

汽车玻璃: 用于汽车应用的钢化玻璃制造, 包括挡风玻璃, 侧窗, 和后窗, 严格的安全标准需要使用钢化玻璃进行乘客保护.

消费电子产品: 应用于制气玻璃屏幕的生产和智能手机显示器, 平板电脑, 和其他电子设备, 耐用性和抗刮擦性对于产品寿命和用户满意度至关重要.

为什么要信任kamrollers:

专业知识和经验: 在行业中拥有多年的经验, kamroller对玻璃制造过程的复杂性有深刻的了解.

对质量的承诺: kamroller致力于提供最高质量的产品, 精心设计和制造以符合严格的行业标准.

创新和技术: kamroller投资于研发,以保持辊设计和制造技术进步的最前沿.

什么是融合的二氧化硅陶瓷辊?

融合的二氧化硅陶瓷辊是主要由融合二氧化硅制成的高性能陶瓷组件 (二氧化硅) 材料. 这些滚筒以其出色的热冲击性而闻名, 高温稳定性, 和低导热率, 使其非常适合各种工业应用, 特别是在高温环境中,例如玻璃制造和连续退火线.

融合二氧化硅陶瓷辊的关键特性是什么?

耐高温: 融合的二氧化硅陶瓷辊可以承受高达1200°C的温度 (2192°F) 没有变形或明显的热膨胀. 低导热率: 此属性可最大程度地减少传热并有助于维持工业过程中的温度均匀性. 热休克阻力: 这些滚筒可以忍受快速变化而不会破裂或破裂. 化学惰性: 融合二氧化硅对大多数化学物质和腐蚀性环境具有抗药性. 机械强度: 他们具有良好的机械强度和耐磨性, 适合处理重负荷和磨料条件.

融合二氧化硅陶瓷辊的典型应用是什么?

玻璃制造: 由于其高温和热冲击性,用于玻璃回火炉和浮玻璃生产线. 冶金: 用于钢和铝生产的连续退火和电镀锌管线. 半导体产业: 在扩散炉和其他高温过程中使用. 陶瓷和难治性生产: 用于窑炉和其他高温射击应用.

您如何维护和照顾融合的二氧化硅陶瓷辊?

定期检查: 检查磨损的迹象, 裂缝, 或定期变形. 打扫: 保持滚筒清洁以防止堆积可能导致不均匀加热或损坏的材料. 适当的处理: 谨慎处理以避免机械损坏. 使用适当的起重设备. 贮存: store, 避免吸收水分的凉爽地方, 在使用过程中可能导致热震动.

使用融合二氧化硅陶瓷辊的优点是什么

提高过程效率: 它们的低导热率和热冲击阻力提高了过程稳定性和效率. 长期使用寿命: 高耐用性和耐磨性和热应力延长了滚筒的运行寿命. 产出质量: 提高玻璃的质量, 金属, 和其他产品通过提供一致的温度控制并最大程度地减少由热变化引起的缺陷.

可以定制熔融二氧化硅陶瓷辊?

是的, 许多制造商提供定制选项以满足特定的申请要求, 包括不同的尺寸, 形状, 和表面饰面. 可以设计自定义滚筒以优化特定工业流程的性能.

选择融合二氧化硅陶瓷辊时应考虑的?

工作温度: 确保辊子可以承受流程的最高工作温度. 负载容量: 验证滚筒是否可以处理应用的机械负载和压力. 兼容性: 考虑化学环境,并确保滚筒材料与将接触的任何物质兼容. 维度的准确性: 选择具有精确尺寸的辊子,以适合您的设备并在操作过程中保持适当的对齐方式.

是否有融合二氧化硅陶瓷辊的局限性?

成本: 由于高质量的材料和制造过程,它们可能比其他类型的滚筒贵. 脆性: 虽然很强, 融合的二氧化硅陶瓷很脆,如果遭受严重的机械冲击或不当处理,可能会破裂.