Glass Tempering Rollers

✦ High temperature resistance: – Steel construction – Special coating protection – Able to withstand high temperature processing

✦ Wear resistance: – High surface hardness – Less wear after long-term use – Reduce replacement costs

✦ Precision machining: – High-precision manufacturing – Reduce glass deformation – Improve processing efficiency and quality

✦ Smooth heat transfer: – Uniform heat transfer design – Avoid uneven glass temperature – Improve glass quality and stability

✦ Customizable: – Customized size and shape according to requirements – Suitable for different glass processing workers – Provide personalized solutions

✦ Reliability: – Rigorously tested and verified – Guaranteed long-term stable operation – Reduced production line downtime

Product Image

Product Certificate

-

DESCRIPTION

-

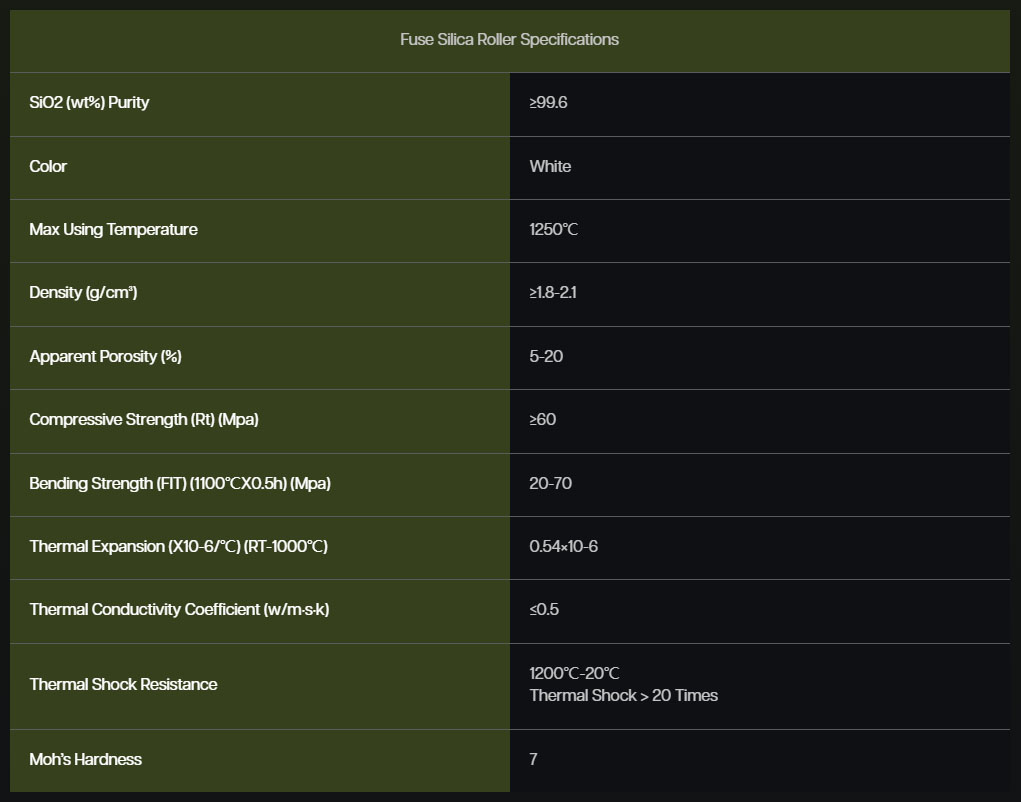

SPECIFICATION

-

FQA

Introducing the Glass Tempering Rollers Series, a comprehensive range of high-quality rollers designed specifically for glass tempering processes. This series offers a wide selection of rollers, each engineered to meet the demanding requirements of glass tempering applications and ensure optimal results. The Rollers Series includes a variety of rollers with different specifications, sizes, and materials to cater to diverse tempering needs. Whether you require fused silica ceramic rollers, quartz ceramic rollers, or other specialized options, this series has you covered.

Crafted with meticulous attention to detail and manufactured using high-quality materials, these rollers are engineered to deliver exceptional performance, reliability, and longevity in demanding glass processing environments. The Glass Tempering Roller Series encompasses a variety of roller types, each tailored to meet the unique needs of glass tempering furnaces, ensuring smooth, uniform, and efficient glass processing from start to finish.

Applications of Glass Tempering Rollers Series

The Glass Tempering Roller is designed for use in a wide range of glass tempering applications, including:

Flat Glass Tempering: Ideal for tempering flat glass panels used in architectural, automotive, and household applications, ensuring enhanced strength, safety, and durability.

Curved Glass Tempering: Suited for tempering curved glass components used in automotive windshields, architectural facades, and specialty applications, providing precise shaping and uniform heating for optimal results.

Specialty Glass Processing: Suitable for tempering specialty glass products such as laminated glass, coated glass, and low-emissivity glass, meeting the stringent quality and performance requirements of specialized applications.

Why Choose the Glass Tempering Rollers Series from Kamroller

Uncompromising Quality: Kamroller is committed to delivering rollers of the highest quality, meticulously engineered and manufactured to meet the strictest industry standards for performance and reliability.

Technical Expertise: With extensive experience in glass processing and materials engineering, Kamroller’s team of experts provides unparalleled technical support and guidance, ensuring customers receive solutions tailored to their specific needs.

Global Reputation: Kamroller has earned a reputation as a trusted provider of glass processing solutions, serving customers worldwide with a commitment to excellence, reliability, and customer satisfaction.

What are Glass Tempering Rollers?

Glass tempering rollers are components used in glass tempering furnaces to support and transport glass sheets during the heating and cooling process. They ensure uniform heating and cooling, which is crucial for producing tempered glass with desired mechanical properties.

How Do Glass Tempering Rollers Work?

Glass tempering rollers rotate to move glass sheets through the tempering furnace. They maintain consistent contact with the glass, allowing for even heat distribution and preventing deformation. The rollers also help in the rapid cooling process, which is essential for tempering the glass.

What Materials are Used for Glass Tempering Rollers?

Glass tempering rollers are typically made from materials that can withstand high temperatures and mechanical stress, such as: Fused silica Ceramic Special high-temperature alloys

Why is Fused Silica Preferred for Glass Tempering Rollers?

Fused silica is preferred due to its high thermal stability, low thermal expansion, and excellent resistance to thermal shock. These properties ensure that the rollers maintain their shape and performance at the high temperatures required for glass tempering.

What are the Key Properties of Glass Tempering Rollers?

High Temperature Resistance: Can withstand the high temperatures in tempering furnaces. Thermal Stability: Maintains dimensional stability under thermal stress. Durability: Resistant to wear and mechanical stress. Smooth Surface: Ensures minimal contact marks on the glass.

How are Glass Tempering Rollers Maintained?

Regular maintenance of glass tempering rollers involves: Inspecting for wear and tear Cleaning to remove glass particles and contaminants Ensuring proper alignment and smooth rotation Replacing damaged or worn-out rollers promptly

What Issues Can Arise with Glass Tempering Rollers?

Common issues with glass tempering rollers include: Surface wear and scratches Deformation due to thermal stress Accumulation of glass debris Misalignment leading to uneven heating and cooling

How Can Glass Tempering Rollers Affect the Quality of Tempered Glass?

The quality of tempered glass can be significantly affected by the condition of the tempering rollers. Smooth and well-maintained rollers ensure uniform heating and cooling, leading to glass with consistent mechanical strength and minimal surface defects.

What is the Role of Glass Tempering Rollers in the Cooling Process?

During the cooling process, the rollers support the glass as it rapidly cools. This rapid cooling induces compressive stresses on the glass surface, which is essential for achieving the tempered glass's strength and safety properties.

Can Glass Tempering Rollers be Customized?

Yes, glass tempering rollers can be customized to meet specific furnace requirements. Customizations can include: Different dimensions and shapes Specialized surface coatings Enhanced material properties for specific applications

How Long Do Glass Tempering Rollers Typically Last?

The lifespan of glass tempering rollers depends on factors such as the operating temperature, the type of glass being tempered, and the maintenance practices. Regular inspection and maintenance can extend the rollers' lifespan significantly.

Are There Alternatives to Fused Silica Rollers?

Yes, alternatives to fused silica rollers include ceramic rollers and rollers made from special high-temperature alloys. Each material has its own advantages and suitability depending on the specific requirements of the tempering process

What are the Safety Considerations When Handling Glass Tempering Rollers?

When handling glass tempering rollers, it is important to: Use appropriate protective equipment to avoid injuries Follow proper installation and alignment procedures Handle with care to prevent damage to the rollers Ensure the furnace is properly cooled before performing maintenance

How Do Glass Tempering Rollers Contribute to Energy Efficiency?

High-quality glass tempering rollers can contribute to energy efficiency by providing consistent and uniform heating, reducing the need for excessive energy consumption, and minimizing heat loss in the furnace.