Lëndë e parë silicë e shkrirë me pastërti të lartë

✦ Product features:- Purity up to 99.99%- Low impurities (metal impurities <10ppm)- Low radial and axial stress- Good optical properties- Excellent thermal stability- Very low thermal expansion coefficien

✦ Application areas: – Optical fiber prefabricated film – Optical glass – Semiconductor materials – Industrial melting system – Chemical reagents

✦ Production process: – Advanced fused quartz production technology – Strict quality control system – Clean production environment – Efficient post-processing

✦ Quality advantages: – Stable product quality – Reliable delivery capability – Professional technical support – Complete ISO9001 certification system

✦ Customer value: – Improve product yield – Reduce production costs – Shorten R&D cycle – Optimize supply chain management

Product Image

Product Certificate

-

DESCRIPTION

-

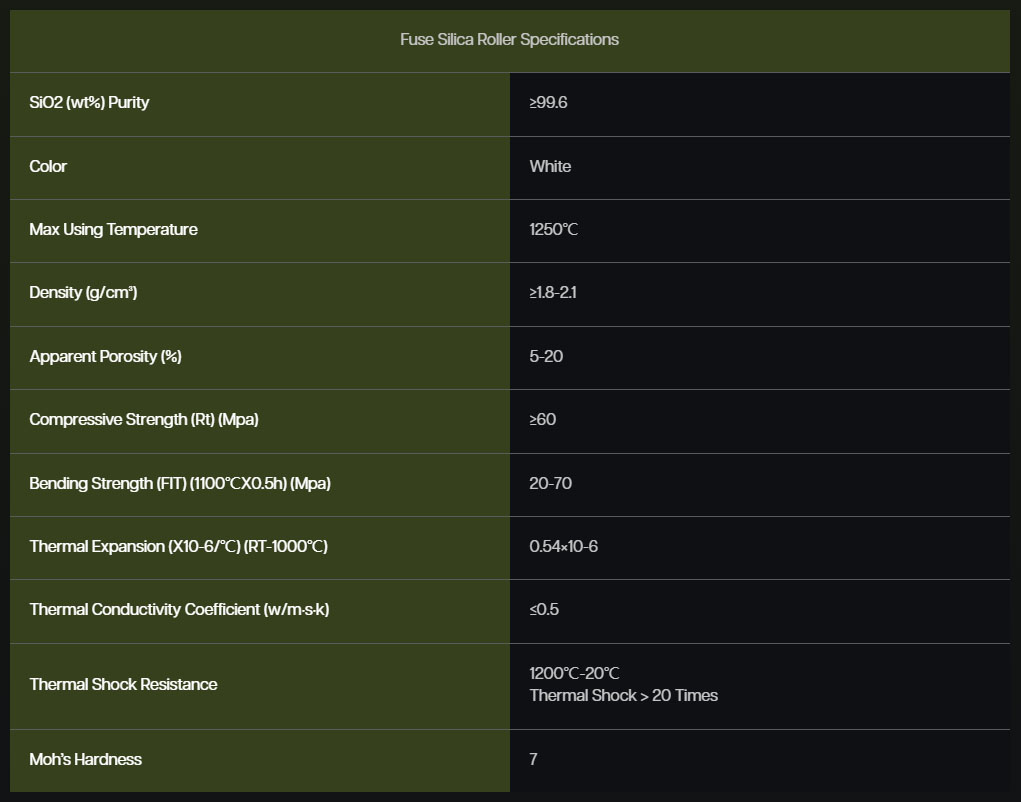

SPECIFICATION

-

FQA

High Purity Fused Silica Raw Material is a premium-grade material renowned for its exceptional purity, thermal stability, and versatility. It is derived from the fusion of high-quality silica sand at extremely high temperatures, followed by a meticulous purification process to remove impurities, resulting in a product of unparalleled quality and consistency. High Purity Fused Silica serves as a fundamental building block in various industries, where precision, reliability, and performance are paramount.

Applications of High Purity Fused Silica Raw Material

✦ Semiconductor Industry: High Purity Silica is extensively used in the semiconductor industry for the production of silicon wafers, optical fibers, and precision components. Its exceptional purity and thermal stability make it an ideal material for critical processes such as photolithography and semiconductor manufacturing

✦ Precision Optics: In the field of optics, High Purity Silica serves as a substrate for optical components such as lenses, prisms, and mirrors.

✦ Glass Manufacturing: High Purity Fused finds widespread use in the glass industry for the production of specialty glass products, including high-performance windows, optical fibers, and laboratory glassware.

✦ Ceramics and Refractories: High Purity Fused Silica serves as a key ingredient in the manufacturing of advanced ceramics and refractory materials.

✦ Aerospace and Defense: In aerospace and defense applications, High Purity Fused Silica is used for the production of precision components, optical systems, and thermal protection materials.

Why Trust Kamroller

Kamroller has established itself as a trusted provider of High Purity Fused Silica Raw Material, with a proven track record of quality, reliability, and customer satisfaction. Here’s why you can trust Kamroller for your raw material needs:

Sigurimi i cilësisë: Each batch of High Purity Fused Silica undergoes stringent quality control checks to ensure consistency, purity, and performance, meeting the highest industry standards and customer specifications.

Technical Expertise: With decades of experience in materials science and engineering, Kamroller’s team of experts provides unparalleled technical support and guidance, assisting customers in selecting the right material for their specific applications.

Custom Solutions: Kamroller offers customized solutions tailored to meet the unique requirements of each customer, providing personalized service and expert recommendations to optimize process efficiency and performance.

What is High Purity Fused Silica?

High purity fused silica is a type of glass consisting of silicon dioxide (SiO2) in an amorphous (non-crystalline) form. It is known for its exceptional thermal, chemical, and optical properties, making it ideal for various high-tech applications.

What are the Main Applications of High Purity Fused Silica?

Semiconductor Manufacturing: Used in photomasks, wafer carriers, and as a substrate for photolithography. Optics: Utilized in lenses, mirrors, and windows due to its high transmission of UV and infrared light. Hapësira ajrore: Employed in high-temperature-resistant components. Telecommunications: Used in optical fibers and other communication devices. Laboratory Equipment: Essential in crucibles, beakers, and other labware due to its thermal stability and chemical resistance.

What are the Key Properties of High Purity Fused Silica?

High Purity: Typically contains over 99.999% SiO2. Thermal Stability: Can withstand extreme temperatures without melting or deforming. Low Thermal Expansion: Exhibits minimal expansion and contraction with temperature changes. Optical Clarity: High transmission of UV, visible, and infrared light. Chemical Resistance: Resistant to most acids, bases, and solvents.

How is High Purity Fused Silica Produced?

High purity fused silica is produced by melting high-purity silica sand at extremely high temperatures. The molten material is then cooled rapidly to prevent the formation of crystals, resulting in an amorphous glass.

What are the Different Forms of High Purity Fused Silica?

Granules: Small, free-flowing particles used in casting and molding processes. Powder: Finely ground particles used in coatings, fillers, and composite materials. Blocks and Rods: Solid forms used in machining custom shapes and parts. Plates and Disks: Flat forms used in optical and semiconductor applications.

What are the Advantages of Using High Purity Fused Silica?

Superior Purity: Ensures minimal contamination in sensitive applications. Thermal Shock Resistance: Can withstand rapid temperature changes without cracking. High Softening Point: Suitable for high-temperature applications. Excellent Optical Properties: Ideal for precision optics and photonics. Qëndrueshmëria: Long-lasting and resistant to wear and corrosion.

What are the Quality Standards for High Purity Fused Silica?

High purity fused silica must meet stringent quality standards, including: Chemical Composition: Ensuring the highest purity levels with minimal impurities. Optical Clarity: Testing for transmission properties across different wavelengths. Thermal Properties: Verifying thermal expansion, softening point, and stability. Mechanical Strength: Assessing hardness, durability, and resistance to stress.

How is High Purity Fused Silica Different from Standard Silica Glass?

High purity fused silica differs from standard silica glass in its purity, optical clarity, and thermal properties. Standard silica glass contains more impurities and has different thermal and mechanical characteristics, making it less suitable for high-tech applications.

What are the Common Challenges in Handling High Purity Fused Silica?

Fragility: High purity fused silica can be brittle and prone to cracking if mishandled. Contamination: Maintaining its purity requires careful handling to avoid introducing impurities. Machining: Working with fused silica requires specialized equipment and techniques to prevent damage.

Where Can I Source High Purity Fused Silica?

High purity fused silica can be sourced from specialized manufacturers and suppliers who meet the rigorous standards required for high-tech and industrial applications. It is important to work with reputable providers to ensure the quality and consistency of the material.