Glass Annealing Roller

✦ High temperature resistance: – Able to withstand the high temperature environment during high temperature glass annealing process, not easy to deform or damage

✦ Made of High-Quality Materials:- Made of high-quality materials to ensure product stability and durability.

✦ Smooth surface: – Smooth surface treatment reduces damage to the glass surface and ensures the quality of the glass.

✦ Precision processing:- After precision processing, ensure the size is accurate and improve production efficiency.

✦ Corrosion Resistance:- It has good corrosion resistance and is suitable for various glass materials

♦ Stable performance: – Maintains stable performance during long-term use to ensure production continuity and stability

♦ Customized service: – Products of different specifications and sizes can be customized according to customer needs.

Product Image

Product Certificate

-

DESCRIPTION

-

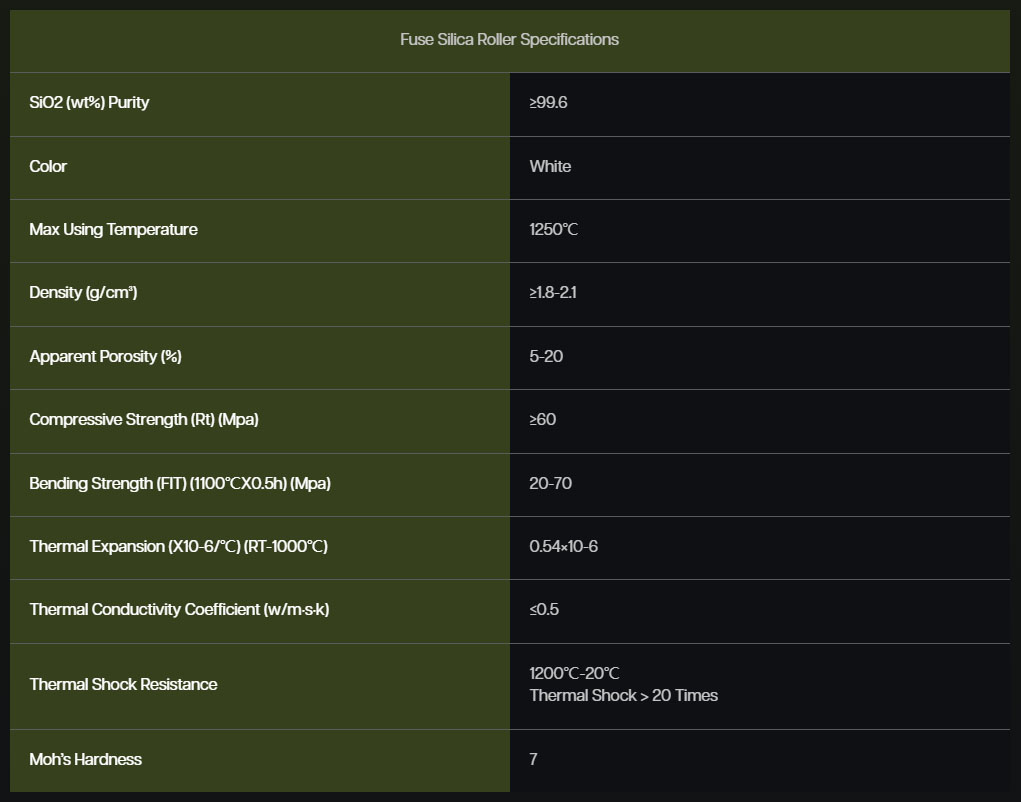

SPECIFICATION

-

Часто задаваемые вопросы

The Glass Annealing Roller is a specialized industrial component meticulously designed to facilitate the annealing process in glass manufacturing. Crafted with precision engineering and utilizing high-quality materials, these rollers provide essential support and guidance to glass products during the annealing process. Whether for flat glass panels or intricate glass components, Kamroller Glass Annealing Rollers ensure uniform heating and controlled cooling, enhancing the mechanical properties and dimensional accuracy of annealed glass products.

Invest in Glass Annealing Rollers and experience the difference precision engineering can make in your glass manufacturing processes. With superior thermal stability, uniform heat distribution, and customizable designs, these rollers ensure optimal annealing results and enhance the quality and performance of annealed glass products.

Applications of Glass Annealing Roller:

Flat Glass Manufacturing: Used in the production of flat glass panels for architectural, Автомобиль, and household applications, Kamroller Glass Annealing Rollers facilitate the annealing process to enhance strength and durability.

Specialty Glass Production: Employed in the manufacturing of specialty glass products, including coated, laminated, and low-emissivity glass, these rollers ensure precise annealing for optimal performance and functionality.

Glass Fabrication: Utilized in the fabrication of precision glass components for optical, electronics, and medical industries, Kamroller Glass Annealing Rollers contribute to the production of high-quality glass products with consistent mechanical properties.

Glassware Manufacturing: Applied in the production of glassware, such as bottles, jars, and containers, these rollers support the annealing process to improve product strength, stability, and resistance to thermal stress.

Glass Art and Decor: Utilized by glass artists and decorators for annealing decorative glass pieces, sculptures, and artworks, Kamroller Glass Annealing Rollers ensure uniform heating and controlled cooling to preserve artistic integrity and quality.

Why Choose Kamrollers:

Гарантия качества: Kamrollers is committed to delivering rollers of the highest quality, meticulously engineered and manufactured to meet the strictest industry standards for performance and reliability.

Technical Expertise: Backed by years of experience in materials science and engineering, Kamroller’s team of experts provides unparalleled technical support and guidance, ensuring customers receive solutions tailored to their specific glass annealing needs.

What is a glass annealing roller?

A glass annealing roller is a critical component in the glass manufacturing process, particularly in the annealing phase. The roller helps to support and transport glass sheets through the annealing lehr, where the glass is gradually cooled to relieve internal stresses and improve its mechanical properties.

Why is the annealing process important for glass manufacturing?

The annealing process is essential because it allows the glass to cool slowly and evenly, preventing the formation of internal stresses that can lead to weaknesses, cracks, or even breakage. Proper annealing ensures that the glass has the desired strength, durability, and thermal resistance.

What materials are used to make glass annealing rollers?

Glass annealing rollers are typically made from materials that can withstand high temperatures and provide a smooth, non-abrasive surface for the glass. Common materials include heat-resistant steels, керамика, and certain types of high-temperature alloys.

How do glass annealing rollers work?

During the annealing process, glass sheets are conveyed through the annealing lehr on a series of rollers. The rollers support the glass and ensure that it moves smoothly and steadily through the different temperature zones, allowing for uniform cooling.

What are the common sizes and specifications of glass annealing rollers?

The sizes and specifications of glass annealing rollers can vary depending on the specific requirements of the glass manufacturing process. Common specifications include roller diameter, length, surface finish, and load-bearing capacity. Custom sizes can often be manufactured to meet specific production needs.

How are glass annealing rollers maintained?

Regular maintenance of glass annealing rollers involves checking for wear and tear, ensuring that the rollers are clean and free of debris, and replacing any damaged or worn-out rollers. Proper lubrication and alignment are also important to ensure smooth operation.

What are the typical challenges faced with glass annealing rollers?

Common challenges include roller wear, surface contamination, misalignment, and thermal fatigue. Addressing these challenges requires regular maintenance, proper material selection, and sometimes the use of advanced coatings or surface treatments to enhance roller performance and longevity.

How can I improve the lifespan of my glass annealing rollers?

To extend the lifespan of glass annealing rollers, ensure regular maintenance, use high-quality materials, and employ proper cleaning and lubrication practices. Кроме того, investing in advanced coatings or surface treatments can help reduce wear and enhance roller durability.

Where can I purchase glass annealing rollers?

Glass annealing rollers can be purchased from specialized suppliers and manufacturers of glass production equipment. It's important to choose a reputable supplier who can provide high-quality rollers that meet your specific production needs.

Can glass annealing rollers be customized?

Yes, many manufacturers offer customization options for glass annealing rollers. This can include specific sizes, materials, and surface treatments to match the unique requirements of your glass production process.