Fused Silica Raw Material / Sand / Powder

✦ Product features:- Purity up to 99.99%- Low impurities (metal impurities <10ppm)- Low radial and axial stress- Good optical properties- Excellent thermal stability- Very low thermal expansion coefficien

✦ Application areas: – Optical fiber prefabricated film – Optical glass – Semiconductor materials – Industrial melting system – Chemical reagents

✦ Production advantages: – Advanced production technology – Strict quality control – Fast delivery cycle – Professional technical support – Customizable according to customer needs

✦ Cost-effectiveness advantage: – High performance-price ratio – Better than similar products – Competitive in the market

Product Image

Product Certificate

-

DESCRIPTION

-

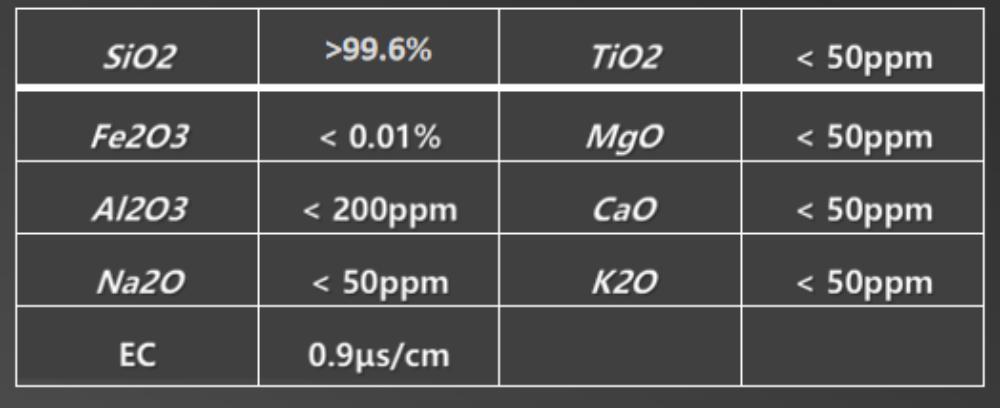

SPECIFICATION

-

FQA

Fused Silica Raw Material stands as the cornerstone of precision engineering, embodying purity, reliability, and versatility. Derived from the fusion of high-quality silica sand at extreme temperatures, this material undergoes meticulous purification to eliminate impurities, resulting in a product of unparalleled quality and consistency. Renowned for its thermal stability, optical clarity, and chemical inertness, Fused Silica Raw Material serves as a fundamental element across diverse industries, empowering innovation and excellence in manufacturing processes.

Applications of Fused Silica Raw Material

emiconductor Industry: Fused Silica finds extensive use in the semiconductor industry, serving as a substrate for silicon wafer production and optical components in photolithography processes. Its exceptional purity and thermal stability contribute to the precise fabrication of semiconductor devices and integrated circuits.

Оптика и фотоника: In the field of optics and photonics, Fused Silica Material is utilized for the manufacturing of lenses, prisms, and optical fibers. Its low thermal expansion coefficient and high transmission of light enable the creation of optical systems with minimal distortion

Производство стекла: Fused Silica Material plays a critical role in glass manufacturing, where it is used to produce specialty glasses with exceptional clarity, strength, and thermal resistance.

Точное машиностроение: In precision engineering applications, Fused Silica Material serves as a foundation for the production of components requiring high dimensional accuracy and stability. Its excellent machinability and resistance to thermal shock make it ideal for use in aerospace, Автомобиль, and medical device manufacturing.

Refractories and Ceramics: Fused Silica Material is a key ingredient in the formulation of refractory materials and advanced ceramics. Its high melting point and resistance to chemical corrosion make it indispensable for lining kilns, furnaces, and reactors in industrial processes

Why Trust Kamroller

Kamroller stands as a trusted provider of Fused Silica Raw Material, offering a commitment to quality, innovation, and customer satisfaction.

Гарантия качества: Each batch of Fused Silica Raw Material undergoes rigorous quality control checks to ensure purity, consistency, and performance, meeting the highest industry standards and customer specifications.

Technical Expertise: With years of experience in materials science and engineering, Kamroller’s team of experts provides unparalleled technical support and guidance, assisting customers in selecting the right material for specific applications.

Custom Solutions: Kamroller offers customized solutions tailored to meet the unique requirements of each customer, providing personalized service and expert recommendations to optimize process efficiency and performance.

Our Factory Image:

Kamroller At The Exhibition:

ISO Certificate:

Что такое плавленый кремнезем?

Fused silica is a type of glass made primarily from high-purity silica. It is known for its excellent thermal stability, низкое тепловое расширение, high optical transparency, and resistance to high temperatures and chemicals.

How is Fused Silica Produced?

Fused silica is produced by melting high-purity silica sand at extremely high temperatures. The molten silica is then cooled to form a glass with unique properties.

What are the Main Applications of Fused Silica?

Fused silica is used in various applications, включая: Optical components (линзы, зеркала, and windows) Semiconductor manufacturing (wafer processing and photomasks) Laboratory equipment (crucibles and beakers) Telecommunications (fiber optics) Aerospace and defense (thermal shields and radomes)

What are the Key Properties of Fused Silica?

High Thermal Stability: Can withstand high temperatures without significant thermal expansion. Низкое тепловое расширение: Minimal expansion and contraction with temperature changes. High Purity: Contains very low levels of impurities, making it ideal for sensitive applications. Optical Transparency: High transmission of ultraviolet (УФ) and visible light. Chemical Resistance: Resistant to most chemicals, including acids and alkalis.

How Does Fused Silica Differ from Quartz?

While both fused silica and quartz are forms of silicon dioxide (SiO2), fused silica is a non-crystalline (amorphous) material, whereas quartz is crystalline. This difference in structure gives fused silica its superior thermal and optical properties.

What are the Common Forms of Fused Silica?

Fused silica can be found in various forms, включая: Rods and tubes Plates and discs Fibers Powder

How is Fused Silica Used in the Semiconductor Industry?

In the semiconductor industry, fused silica is used for its high purity and thermal stability. It is employed in the production of photomasks, wafer carriers, and as a material for various processing equipment.

What is the Role of Fused Silica in Optical Applications?

Due to its high transparency and low thermal expansion, fused silica is ideal for making optical components such as lenses, зеркала, and windows used in scientific instruments, cameras, and telescopes

How Does Fused Silica Benefit Telecommunications?

In telecommunications, fused silica is used to make fiber optic cables, which rely on the material's high optical clarity and low signal loss to transmit data over long distances.

What are the Safety Considerations When Handling Fused Silica?

When handling fused silica, it is important to: Use protective equipment to avoid inhalation of silica dust, which can be harmful. Handle with care to prevent breakage, as the material can be brittle. Follow proper storage guidelines to maintain the material's purity and integrity.

Can Fused Silica Be Customized?

Yes, fused silica can be customized to meet specific requirements, such as different shapes, sizes, and surface finishes, depending on the application.

What is the Environmental Impact of Fused Silica?

Fused silica production involves high energy consumption due to the high melting temperatures required. Однако, the material itself is non-toxic and can be recycled or safely disposed of in accordance with local regulations.