Automotive Bending Forming Mold

✦ Precision molding:- Using high-precision processing technology to ensure high mold molding accuracy to meet the strict requirements of automotive parts.

✦ Durability: – Using high-quality materials and advanced surface treatment technology to enhance the wear resistance and corrosion resistance of the mold and extend its service life

✦ Efficient production: – Design advanced mold structure and manufacturing process to improve production efficiency, shorten cycle and reduce cost.

✦ Versatility: – Flexible design and processing capabilities to meet the molding needs of parts of different shapes and specifications.

✦ Cost-effectiveness: – Optimize design and manufacturing processes, reduce production costs and enhance corporate competitiveness.

♦ Customized service – Customized molds according to customer needs, providing personalized solutions to meet the needs of different automobile manufacturers.

Product Image

Product Certificate

-

DESCRIPTION

-

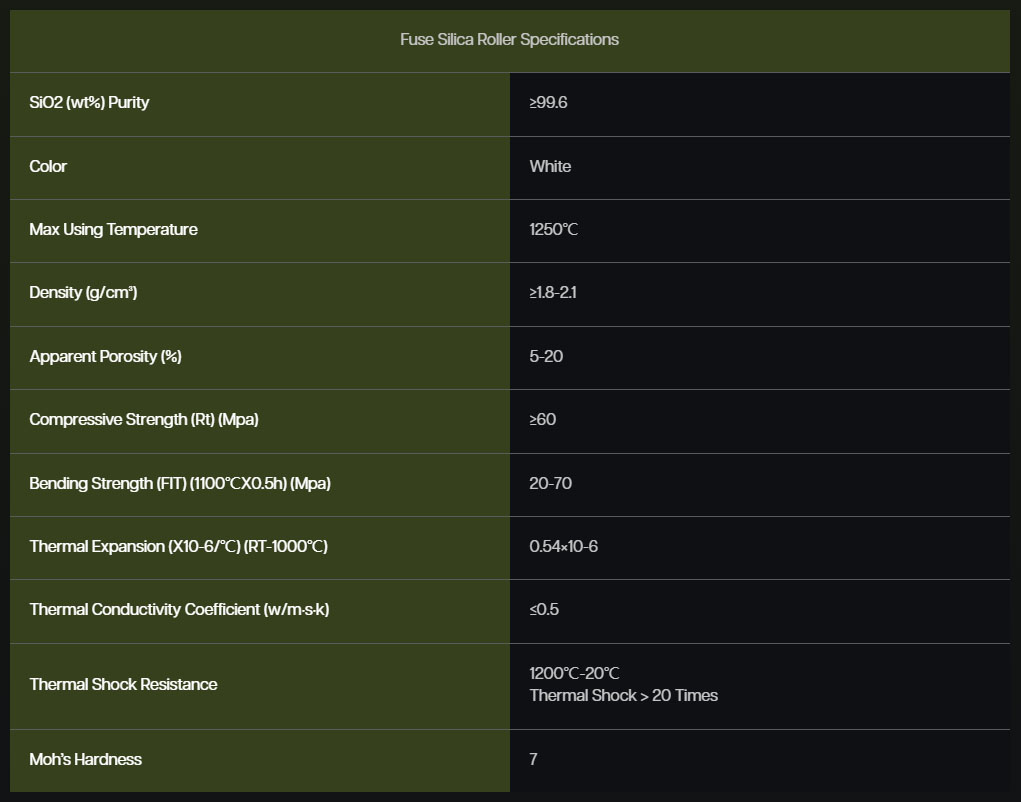

SPECIFICATION

-

FQA

Introducing our Automotive Bending Forming Mold, a precision tool designed to meet the demanding requirements of automotive manufacturing processes. This specialized mold plays a critical role in accurately and efficiently shaping and forming various automotive components.

The Automotive Bending Mold is crafted with utmost precision and attention to detail to ensure optimal results. It is specifically engineered to accommodate automotive parts’ unique bending and forming requirements, including sheet metal components, tubes, and other structural elements. Its user-friendly design and ease of operation allow for seamless integration into existing manufacturing systems, minimizing downtime and optimizing productivity.

The Automotive Bending Forming Mold stands as a testament to precision engineering, meticulously crafted to meet the stringent demands of the automotive industry. Engineered with cutting-edge technology and expertise, this specialized mold plays a pivotal role in shaping and forming automotive components with unparalleled accuracy and reliability. Designed to withstand the rigors of automotive manufacturing, the Automotive Bending Forming Mold ensures consistent and precise results, making it an indispensable tool in the production of high-quality automotive parts.

Key Features of the Automotive Bending Forming Mold

High-Quality Materials: Crafted from premium materials, such as hardened steel or aluminum alloys, the mold offers exceptional durability and longevity, ensuring reliable performance even in high-volume production environments.

Precision Machining: Each Bending Forming Mold undergoes precision machining to tight tolerances, guaranteeing accurate and consistent shaping of automotive components with minimal variation.

Customizable Designs: The mold’s design can be customized to accommodate various automotive components, allowing for versatility and adaptability in manufacturing processes.

Термическая стабильность: The Bending Forming Mold is engineered to withstand high temperatures and thermal cycling, maintaining dimensional stability and performance over extended production runs.

Efficient Cooling Systems: Incorporating efficient cooling systems, the mold ensures rapid and uniform cooling of formed automotive components, minimizing cycle times and enhancing productivity.

Applications of the Automotive Bending Forming Mold

The Automotive Bending Forming Mold finds wide application in the automotive industry, включая:

Body Panels: Used in the production of body panels, such as doors, fenders, and hoods, to achieve precise bending and forming of sheet metal components.

Chassis Components: Employed in the manufacturing of chassis components, such as frame rails and cross members, to shape and form structural elements with accuracy and consistency.

Interior Trim: Utilized for shaping and forming interior trim components, such as dashboard panels and door trims, to achieve seamless integration and precise fitment.

Exhaust Systems: Critical in the fabrication of exhaust systems, including pipes and mufflers, to ensure precise bending and forming for optimal performance and durability.

Suspension Parts: Essential in the production of suspension components, such as control arms and steering knuckles, to achieve accurate shaping and forming for superior handling and stability.

Why Trust Kamrollers

Kamrollers has earned a reputation as a trusted leader in precision engineering, with a commitment to delivering high-quality products and exceptional customer service. Here’s why you can trust Kamroller for your Automotive Bending Forming Mold needs:

Expertise and Experience: With extensive experience in automotive manufacturing, Kamroller possesses the knowledge and expertise to provide high-quality molds customized to meet the specific needs of each client.

Гарантия качества: Every Bending Forming Mold is subjected to stringent quality control inspections to guarantee precision, reliability, and optimal performance, adhering to the highest industry standards.

Custom Solutions: Kamroller delivers tailored solutions to meet unique customer needs, offering personalized service and expert guidance throughout the entire process.

Automotive bending and forming molds play a crucial role in the automotive manufacturing process. They transform flat metal materials into desired shapes by applying pressure and heat. These molds are used to produce key components such as car bodies, doors, hoods, и еще, ensuring the structural integrity and aesthetic appeal of the vehicles.

The design and manufacturing of these molds require high precision and durability to withstand the high-intensity working environment and complex forming demands. Advanced mold technology not only enhances production efficiency but also improves the quality and consistency of the final products.

What is an automotive bending forming mold?

An automotive bending forming mold is a specialized tool used in the automotive industry to shape metal parts through bending and forming processes. These molds are designed to create precise bends and contours in metal sheets, which are then used in the assembly of various automotive components.

How does a bending forming mold work?

A bending forming mold works by applying force to a metal sheet, causing it to bend and take on the shape of the mold. This process typically involves a press machine that uses a punch and die setup. The punch presses the metal into the die, creating the desired bend or shape.

What materials are commonly used with bending forming molds?

Common materials used with bending forming molds include various metals such as steel, aluminum, and other alloys. These materials are chosen based on their strength, flexibility, and suitability for the specific automotive part being produced.

What are the key benefits of using bending forming molds in automotive manufacturing?

Точность: Bending forming molds ensure high precision in creating complex shapes and bends. Efficiency: These molds can produce parts quickly and consistently, improving manufacturing efficiency. Cost-Effective: Once a mold is created, it can be used to produce large quantities of parts, reducing overall production costs. Quality: Molds help maintain consistent quality and accuracy across all produced parts.

What are the types of bending forming molds?

V-Bending Mold: Used for simple, straight bends. U-Bending Mold: Creates U-shaped bends in the metal. Edge Bending Mold: Bends the edges of metal sheets. Channel Bending Mold: Forms channel shapes with varying depths and widths. Air Bending Mold: Uses less force and allows for more flexibility in bend angles.

How are bending forming molds maintained?

Cleaning: Removing debris and lubricants to prevent wear. Inspection: Checking for signs of wear or damage. Lubrication: Applying appropriate lubricants to reduce friction and wear. Calibration: Ensuring the mold is properly aligned and calibrated for precise operation.

What are the challenges associated with bending forming molds?

Material Springback: Metals tend to spring back after bending, requiring adjustments in the mold design. Tool Wear: Frequent use can cause wear and tear, necessitating regular maintenance and replacement. Complex Shapes: Creating molds for complex shapes requires precise engineering and can be time-consuming.

How do you select the right bending forming mold for a project?

Material: Choose a mold compatible with the type of metal being used. Part Design: Ensure the mold can produce the desired shape and bends. Production Volume: Select a mold that can handle the required production volume efficiently. Precision Requirements: Consider the precision needed for the automotive part and select a mold that meets those specifications.

What advancements are being made in bending forming mold technology?

Automation: Incorporating automated systems for increased efficiency and precision. Advanced Materials: Using stronger and more durable materials for longer-lasting molds. Computer-Aided Design (CAD): Enhancing mold design accuracy and customization. 3D Printing: Utilizing 3D printing for rapid prototyping and mold production.