Fused Silica Barrels

✦ Excellent Heat Resistance: Made Of High-Purity Fused Quartz Material, It Can Withstand High Temperature Furnace Environment.

✦ Excellent Chemical Stability: Anti-Corrosion Properties, Suitable For Various Chemical Reagents And Solvents

✦ Precise Processing And Dimensional Stability: Precise Manufacturing Process, Precise And Stable Dimensions, Suitable For Precision Instrument Parts

✦High Transparency And Low Ripple: Optimum Optica Properties, Apta pro laser Systems Et Optical Components

Ultra- Low Thermal Expansion Coefficient: Maxime Minimum Scelerisque Expansion euismod, Princeps stabilitas, Idoneum pro summus praecisione Scelerisque Imperium Management

♦ Environmentally amica et pollutio-liber: non nocivis substantiae, viridi environmentally- amica materiae, mundus productionem processus

Product Image

Fused Silica Barrels Certification

ISO9001, certificatione CE,RoHS environmental certificatione

Product specifications: Diameter interior: 20-150 mm, Longitudo: 50-500 mm, Murus crassitudine: 2-10 mm

-

DESCRIPTIO

-

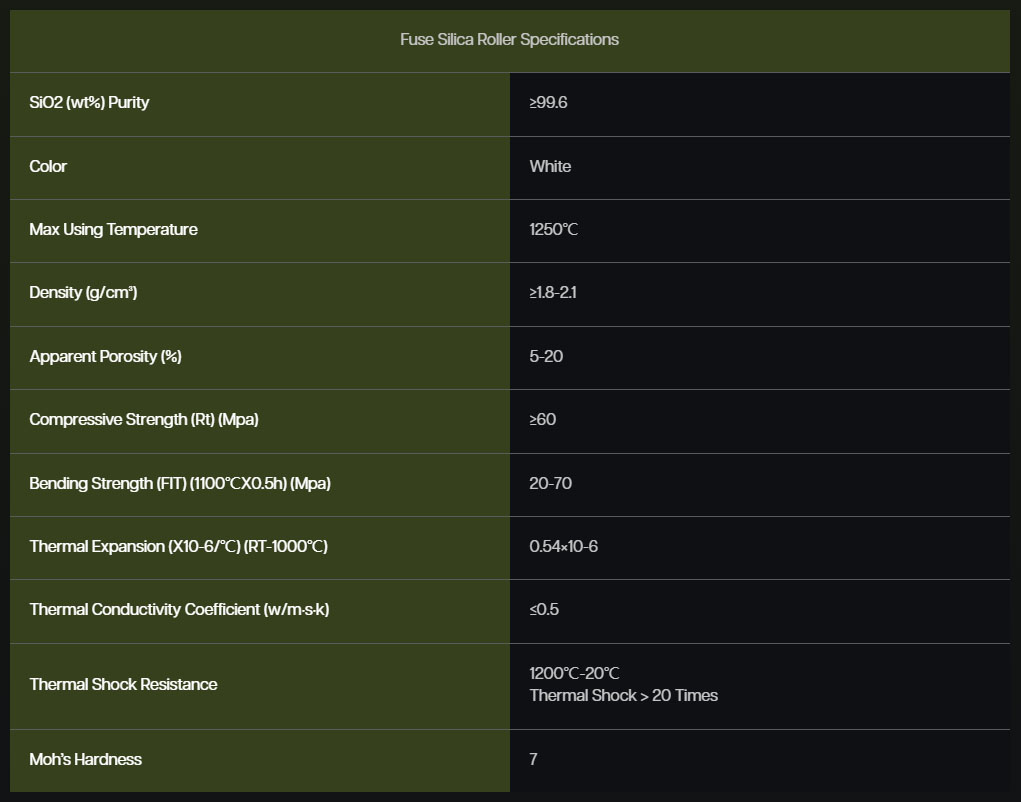

SPECIFICATION

-

FQA

Fused Silica Barrels, also known as Fused Silica Rollers, are high-purity cylindrical components made from fused silica, primarily composed of silicon dioxide (SiO2). These barrels are engineered to offer exceptional performance in various industrial applications, particularly those requiring high-temperature resistance, chemical stability, and mechanical strength. With a purity level of ≥99.6%, Fused Barrels are ideal for processes that demand minimal contamination and superior material integrity.

Including fused silica plates, fused silica crucibles, material bowls for glass furnaces, ends, punch, stirring slurry, uniform cylinders, etc., widely used in vertical glass drawing pipelines and glass-ceramic production lines, also according to customer drawings products in other complex shapes. Due to quartz ceramics’ excellent thermal shock resistance, preheating the hot state is unnecessary; it is resistant to glass corrosion, has no pollution to the glass liquid, has high strength, and has a long service life.

Features of Fused Silica Barrel

✦ High Purity: Made from 99.99% pure silicon dioxide, fused silica barrels exhibit superior purity, ensuring no contamination in sensitive processes.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.Chemical Resistance: Fused silica is highly resistant to acids, bases, and other aggressive chemicals, ensuring longevity and reliability in harsh environments.

✦ Low Thermal Expansion: The minimal thermal expansion of fused silica prevents cracking and maintains structural integrity even under rapid temperature changes.

✦ Optical Clarity: Fused silica’s optical clarity allows for precise monitoring and measurement, crucial in applications like spectroscopy and photonics.

Applications of Fused Silica Barrels

Semiconductor Manufacturing: Used in the fabrication of semiconductor devices, fused barrels provide the high purity and thermal stability necessary for precision etching and deposition processes.

Aerospace and Defense: In these sectors, the exceptional thermal properties and durability of silica are vital for components exposed to extreme conditions.

Scientific Research: Laboratories use silica barrels in experiments that require high-temperature environments and resistance to chemical reactions.

Medical Devices: The biocompatibility and non-reactive nature of fused silica make it suitable for use in medical and dental instruments.

Optical Fiber Production: Fused silica barrels are integral in the manufacturing process of optical fibers, where their clarity and stability ensure high-quality output.

Our Fused Barrels are the perfect choice for industries that demand high performance, reliability, and durability. With their advanced material properties and precise engineering, they ensure optimal performance in the most challenging environments. Choose our Fused Silica Barrels for superior quality and unmatched performance.

Why Trust Kamroller

Kamroller stands at the forefront of fused silica technology, committed to delivering products that meet the highest standards of quality and performance. Here’s why you can trust Kamroller for your fused silica barrel needs:

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Customer Focus: Kamroller prioritizes customer satisfaction, offering personalized service and technical support to meet your specific needs.

Sicut materia clavis in semiconductore industriae et agro optico, conflata vicus cadi momenti applicationis valorem et evolutionem spem habent. Per optimizing vestibulum processus et productum qualitas emendans, melius possumus necessitatibus occurrere agrorum diversorum et promovere evolutionem et innovationem cognatorum industriarum.

Quid sunt Fused Silica Barrels

Fused Silica Barrels: Materia magni momenti adhibita industria semiconductoris cum summa puritate et resistentia caloris excellenti

Quae sunt commoda doliis silicis mixtis??

- Princeps caliditas stabilitas: Potest sustinere summa temperaturis sine liquefactione vel deformatione - Chemical inertness: Bonum corrosio resistentiae variis chemicis - Optical diaphanum**: Praeclara est perspicuitas optica et apta ad processui optica et deprehensio. - Subtilitas processus **: Accurate discursum esse potest in varias formas ad diversas necessitates occurrendas.

Quae sunt principalis application areas of silica cadi fusi?

- Semiconductor fabricandi**: key components fabricare solebat processus semiconductor instrumenti sicut machinis lithographiae et depositio cinematographica tenuia. - Instrumenta optica**: apta ad fabricandum lentium et partium opticorum instrumentorum opticorum ut telescopia et spectrometris. - Experimenta chemica: ut repono vasa ad chemica reagentia, summus temperaturis et corrosivis substantiis resistunt.

Quid sit processus fabricandi cupas silicae fusi?

- Exustio**: Calefacit materiam summam puritatem silicam in statu fusili. - CUMATIUM**: Mola silica fusilis in dolium figura utens forma vel subtilitate machinis technologiae. - Annealing**: Accentus interni eliminando moderando temperiem et tempus ut meliorem calorem resistendi ac stabilitatem dolii vicus fusi.

Quae sunt problemata communia et solutiones doliis vicus mixtis? .

- Scelerisque inpulsa rimas **: Rimas videntur sub celeri temperatus mutationes. - Solutio**: Optimize processus furnum ad meliorem stabilitatem thermarum de dolio vicus fusi. - Chemical exesa**: Damnum mordax substantiarum ut fortis acida et alcali. - Solutio**: Melior est superficies efficiens vel lego materiae cum fortior corrosione resistentia. - Figura impropria**: Figura deviationis vel irregularitatis, quae fit in vestibulum processus. - Solutio**: Optimize vestibulum processus, qualis confirma imperium, et curare productum accuracy. - Internum bullae**: Gases in materia in dolio capiuntur, afficiens suum servitium vita et perficiendi. - Solutio**: Optimize processus materialis purificationis, redigendum Gas residua, et amplio materia qualis.

Quid sit modus conservandi dolium conflatum vicus?

- Iusto purgatio **: Utere speciali agente purgatio ad purgandum superficiem ad faex et sordes removendum. - Vitare occursum **: Diligenter tractare et vitare conflictum cum obiectis duris ne superficies exasperat vel damnum. - Proprium repono**: Vitare longum tempus nuditate ad caliditas vel humida environment, et eligere aridam et uentilandam repono locus. - Iusto inspectione **: Regulariter reprehendo superficies ad rimas vel damnum, et reficere vel reponere in tempore