Fused Silica Roller For Glass Tempering Furnace

✦ High temperature resistance: – Can it withstand temperatures up to 1800 degrees Celsius? – What industrial fields are commonly used in high temperature environments?

✦ Excellent chemical stability: – Corrosion-resistant, not attacked by chemical substances

– Applicable to various chemical environments without affecting product quality

✦ Excellent surface finish: – The surface is smooth and not easy to be scratched or worn- Maintain the high-quality appearance of the product surface

✦ Precise size control: – Precision manufacturing process ensures accurate product size- Different specifications can be customized to meet different needs

✦ Good thermal conductivity:- Excellent thermal conductivity helps with temperature control and uniform heating- Improve production efficiency and reduce energy consumption

Product Image

Product Certificate

-

DESCRIPTION

-

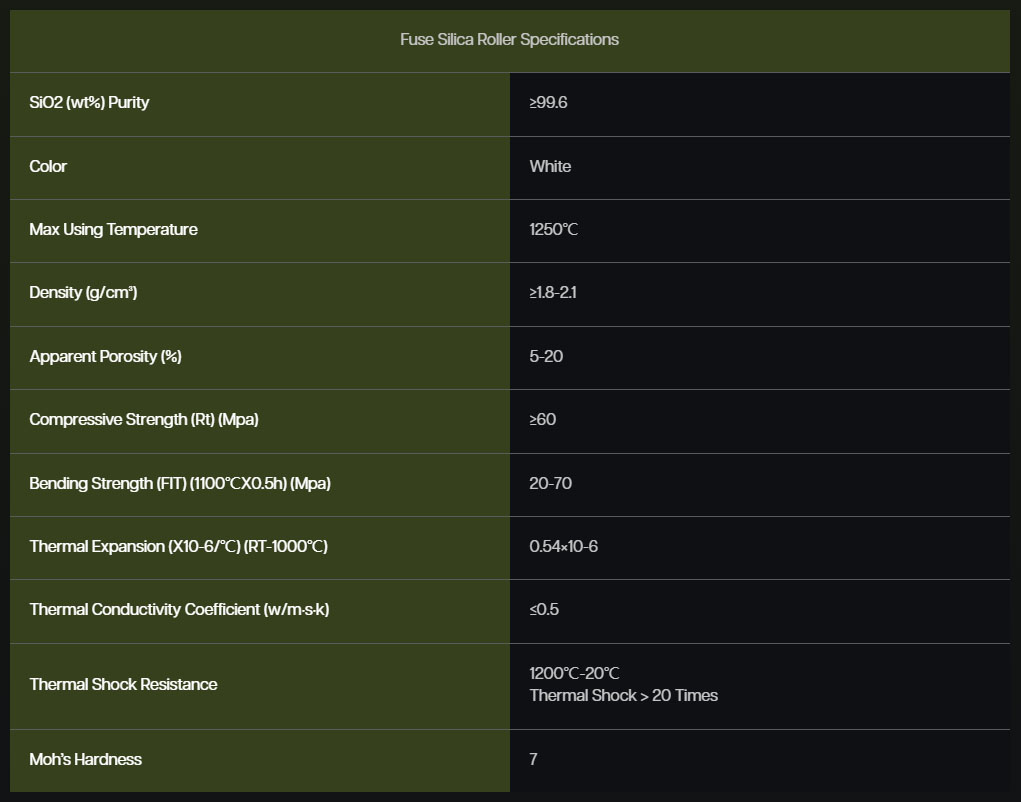

SPECIFICATION

-

FQA

Introducing the Fused Silica Roller for Glass Tempering Furnace, a pinnacle of precision engineering designed to meet the rigorous demands of glass tempering processes. Crafted from high-purity fused silica, these rollers offer unparalleled thermal stability, durability, and reliability, ensuring exceptional performance in high-temperature environments. Engineered to withstand the extreme conditions of glass tempering furnaces, the Fused Silica Roller sets a new standard for quality and efficiency in glass processing.

Applications of Fused Silica Roller for Glass Tempering Furnace

The Fused Silica Roller finds widespread application in the glass industry, particularly in glass tempering furnaces, where it serves as a critical component for:

Tempering Process: These rollers facilitate the uniform heating and rapid cooling of glass sheets during the tempering process, resulting in enhanced strength, durability, and safety of tempered glass products.

Conveyor System: Installed as part of the conveyor system within the tempering furnace, Fused Silica Rollers ensure smooth and stable transportation of glass sheets through the heating and cooling zones, minimizing breakage and defects.

uality Control: By maintaining precise control over glass movement and temperature distribution, these rollers contribute to the consistent quality and performance of tempered glass products, meeting industry standards and customer specifications.

Investing in the Fused Silica Roller for Glass Tempering Furnace is a strategic choice that promises to elevate your glass processing operations to new heights of efficiency and quality. Engineered with precision and crafted from high-purity fused silica material, these rollers offer unparalleled thermal stability, durability, and reliability, ensuring consistent and precise glass tempering processes. By opting for these rollers, you’re not only enhancing the performance and longevity of your equipment but also maximizing efficiency, reducing downtime, and ultimately, improving your bottom line.

Key Features of Fused Silica Roller for Glass Tempering Furnace

High Thermal Stability: Engineered from premium fused silica material, these rollers boast exceptional thermal stability, allowing them to withstand the intense heat of glass tempering furnaces without deformation or degradation.

Low Thermal Expansion: With minimal thermal expansion characteristics, the Fused Silica Roller maintains its shape and dimensions even under rapid temperature changes, ensuring precise and consistent glass processing.

Uniform Surface Finish: Each roller is meticulously machined to achieve a smooth and uniform surface finish, minimizing friction and ensuring precise glass movement within the tempering furnace.

Chemical Resistance: Fused silica material offers excellent resistance to chemical corrosion, protecting the rollers from damage caused by molten glass and harsh cleaning agents, thus prolonging their lifespan and maintaining performance.

Customizable Design: Kamroller offers customizable designs to accommodate various glass thicknesses and processing requirements, ensuring optimal performance and efficiency in glass tempering operations.

Why Trust Kamroller

Kamrollers is renowned for delivering high-performance rollers for industrial applications, emphasizing quality, innovation, and customer satisfaction. Here’s why Kamroller is your go-to choice for glass tempering furnace solutions:

✦ Expertise and Experience: With years of experience in precision engineering, Kamroller has the knowledge and expertise to deliver superior rollers tailored to meet the unique requirements of glass tempering processes.

✦ Quality Assurance: Each Fused Silica Roller undergoes rigorous quality control checks to ensure thermal stability, dimensional accuracy, and reliability, meeting the highest industry standards for glass processing equipment.

✦ Custom Solutions: Kamroller offers customized solutions to address specific customer needs and furnace configurations, providing personalized service and expert guidance throughout the selection and installation process.

What is a fused silica roller?

A fused silica roller is a high-precision roller made from high-purity silicon dioxide (SiO2). These rollers are known for their exceptional thermal and mechanical properties, making them suitable for various industrial applications

What are the key features of fused silica rollers?

High Purity: Made from high-purity silicon dioxide. Thermal Stability: Very low thermal expansion and high resistance to thermal shock. High Strength: Capable of withstanding significant stress and load. Smooth Surface: Reduced friction and wear. Chemical Resistance: Resistant to most chemicals, including acids and bases. High Temperature Resistance: Can operate at extremely high temperatures.

What are the common applications of fused silica rollers?

Glass Manufacturing: Used for conveying hot glass sheets in the production of flat glass. Semiconductor Industry: Used for wafer handling and processing. Metallurgy: Employed in high-temperature furnaces and kilns. Solar Panel Production: Integral in the production processes involving high temperatures. Ceramics Manufacturing: Used for conveying ceramic products through kilns. Textile Industry: Applied in high-temperature and chemical-resistant processes.

Why are fused silica rollers preferred in high-temperature applications?

Fused silica rollers are preferred because of their low thermal expansion, high resistance to thermal shock, and ability to operate at very high temperatures without deforming or degrading.

How do fused silica rollers contribute to the glass manufacturing process?

In glass manufacturing, fused silica rollers ensure smooth and defect-free conveyance of hot glass sheets. Their high thermal stability and smooth surface help maintain the quality of the glass products.

Can fused silica rollers withstand chemical exposure?

Yes, fused silica rollers are highly resistant to most chemicals, including acids and bases, making them suitable for use in chemically harsh environments.

What maintenance is required for fused silica rollers?

Fused silica rollers typically require minimal maintenance due to their durability and resistance to wear. Regular inspections to check for surface damage or contamination are recommended to ensure optimal performance.

Are there any limitations to using fused silica rollers?

While fused silica rollers have many advantages, they can be brittle and may crack or chip if subjected to severe mechanical shocks or impacts. Proper handling and installation are essential to prevent damage.

How do fused silica rollers compare to other types of rollers?

Compared to other materials, fused silica rollers offer superior thermal stability, chemical resistance, and a smoother surface. They are often chosen over other materials for applications requiring these specific properties.

Can fused silica rollers be customized for specific applications?

Yes, fused silica rollers can be customized in terms of size, shape, and surface finish to meet the specific requirements of different industrial applications.