Top 5 Reasons Why You Need Ceramic Roller

2024.06.21admin

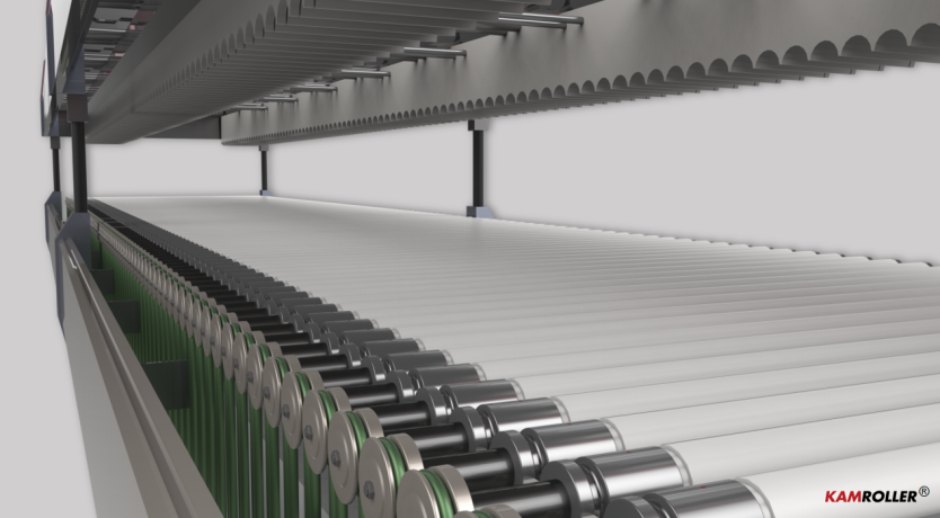

The ceramic roller is a cylindrical component usually made up of silicon nitride or alumina that serves the industrial needs in many sectors. That is why these rollers are very effective in conditions that are rather severe; this is why engineers and producers are quite eager to apply them. In this article, we will look into the properties, ઉપયોગ કરે છે, and advantages of these rollers in this interesting field. We shall also discuss the different types of this roller and the factors that can help you select the most suitable one for your application.

Understanding Ceramic Rollers: A Relation of Strength and Performance

Therefore, the first and most significant attribute of a ceramic roller is its material makeup. Ceramics, as compared to ordinary metallic rollers, possess certain characteristics that are quite effective for several industrial applications. A closer look at a few crucial traits is provided below:

- Superior Wear Resistance:

When compared to the metal rollers these have a much longer life expectancy because of the high level of durability and strength that is offered by the material. This makes the costs of maintenance to be relatively low and the production rates to be high.

- High-Temperature Performance:

Even though these materials are exposed to high temperatures up to extremely high levels; they do not deform or lose their shape. They are hence suitable for use in kilns, furnaces as well as other areas of high temperatures.

- Corrosion Resistance:

The ceramic materials are naturally very resistant to corrosion, this, therefore, makes them perform their duties as expected even in corrosive environments. This enhances the durability of the long term since it does not provide room for the screws to rust or get weak.

- Minimal Friction:

Some of the ceramic rollers are characterized by very low values of the coefficients of friction. In conveyor systems and other applications where smooth rolling is desirable, this means that less energy is being used.

A Spectrum of Choices: The Different Kinds of Ceramic Rollers

All these rollers are not the same. Based on material composition, the following is a breakdown of some popular types:

- Alumina Ceramic Rollers:

The ceramic rollers that are most commonly used are alumina rollers since they combine the factors of low cost, high-temperature operation, and high durability.

- Silicon Nitride Ceramic Rollers:

Due to the fact that they are very strong and hard, these rollers are recommended for high-wear applications. It is also important to note that they have a low coefficient of thermal expansion which is quite important for applications that require accurate dimensional stability.

Beyond Durability: Unveiling the Diverse Applications of Ceramic Rollers

The ceramic roller is acclaimed as the unsung hero of many industries because of the features exhibited by the rollers that are way beyond the aspect of durability. Now let’s delve into the subject of ceramic roller applications and discover how versatile these versatile components are in order to achieve the best results and maintain smooth operation in a wide range of industries.

Providing Dimensional Stability in the Manufacturing of Paper:

- Suppose that there is a paper sheet of the right shape coming out of an assembly line. Thus, the success can be attributed to the use of ceramic rollers to a great extent. Thus, paper webs are capable of moving without getting distorted in several processing steps due to their stability. This becomes high-quality paper all the time, this is a clear indication that the paper-producing company is reliable.

Control and Accuracy in the Printing Sector:

- The printing industry is very much dependent on the precise control of several factors. These are applied in printing presses for two major functions. It is characterized by very low friction and relatively high thermal stability. They first ensure that there is no paper jam and this enhances smooth paper feeding which in turn ensures that there are no errors in the printing. Second, they prevent damaged prints during the drying process because they can withstand high temperatures.

Handling Delicate Materials in the Electronics Sector:

- Due to the fact that they are often complex, electronic components must be handled with delicacy. This is where ceramic rollers really excel. It protects delicate parts in the course of movement and processing in the course of transportation in the electronics industry due to their very smooth surface finish. This ensures the smooth running of the electronic gadgets that we cannot do without in our day to day activities.

Selecting the Right Ceramic Roller: Key Considerations

When it comes to the selection of the best ceramic roller these are the guidelines that can be followed. Some factors which affect the selection procedure include; factors that enhance the advantages of these flexible components and improving performance. The following list of important factors will help you choose the ideal ceramic roller:

- Comprehending Your Application:

A key role is played by the main function of the roller. Do you need a roller to feed the material to the machine or to direct it with high precision or transfer it? Your choices will be restricted once you have decided on the position.

- Load Capacity Is Important

Suppose that there is a conveyor belt which is carrying large items that are heavy in weight. Selecting a roller that is not very heavy will lead to early damage. Before you buy a roller ensure that you know the amount of load that the roller will be required to bear when in use.

- Temperature:

Performance can be awfully affected by heat for example when an athlete is in a race. Find out the likely temperature that the application operates or will operate in. Alumina is one type of ceramic material that offers reasonably good balance at moderate operating temperatures. As a result of their high thermal conductivity, silicon nitride rollers find their application in high temperature applications.

- Chemical Suitability:

Does the roller come across chemicals? Some items are susceptible to corrosion by certain chemical solutions. Knowing the possible chemical environment, one can choose the ceramic roller that will give the maximum resistance, thus serving the purpose and lasting longer.

- Surface Quality Is Important:

Think of the kind of contact you would want the roller to have with the substance it is to come into contact with. In applications such as moving fabrics or electronic components, the surface finish is critical as it decreases the friction. On the other hand, there is a possibility of using a surface that is slightly rough in jobs that require more friction such as controlling paper webs.

The Benefits and Compelling Value Proposition of Ceramic Rollers

The modern world is characterized by increased competition in industries hence quality and efficiency are essential. These rollers are a game changer because they give the consumers a superior value proposition that is more than just extended lifespan. Now, let us look at the principal benefits that make it possible to consider this roller as a profitable investment for companies in various fields of activity.

- Lower Maintenance Costs:

Ceramic roller is more durable than the metallic one as the latter easily gets worn out. This means that there is reduced time of maintenance and less frequent replacement of the part. Fewer disturbances mean that the production flow is smoother and this reduces the expenses and increases the yield.

The best production requires that performance has to be steady. They fulfil this assurance. Their durability to wear and tear minimizes the time that the components need to be fixed or replaced. Therefore, your production process will be enhanced to produce more and meet the set deadlines as compared to the traditional methods.

- Consistent Product Quality:

Maintaining quality in the product that you are producing is very important and this calls for accuracy and control. They provide perfect guidance and processing for the material due to its dimension stability and wear resistance. This helps eliminate inconsistencies and defects, and therefore enhances the final output to meet your very strict standards.

Why Ceramic Rollers Matter: Industrial Exceptional Heroes

Imagine the world where there is no proper material handling and management of goods, the quality of the products is not guaranteed and there are no smooth production lines. Despite the fact that these parts are rather notorious for being overlooked, they are indeed useful in numerous types of businesses. It is time to discuss the importance of ceramic rollers and the effect they have on the improvement of the efficiency of the manufacturing process.

- Unmatched Durability:

These rollers are highly durable in comparison with the other metal rollers that can easily get rusted. This makes them less prone to wear and tear, hence minimizing on the time and frequency of maintenance and thus enhancing production. Huge costs are cut and there is increased production as a result of this.”

- You Can Rely On Our Accuracy:

They are characterized by standard sizes. Even when laden to the utmost, they continue to hold their shape so as to ensure that materials will be directed and managed as efficiently as possible. This translates into high quality products that are required for the dependable production system.

- A Wide Range of Applications:

Their design is not complex in any way and does not mislead you in any way. They are applying in many fields. They are versatile and can be used to perform various tasks from controlling the movement of sensitive fibers used in textiles to food transportation in hygienic conditions.

- Above and Beyond the Observable:

Besides the intended purposes, these rollers have several additional applications. In some varieties, due to low friction they may consume less energy. In addition, they are suitable for use in hostile chemical conditions owing to the fact that they do not easily corrode.

Conclusion:

The contemporary world is characterized by the enhancement of the industrial sector, which emphasizes effectiveness and quality. We know how much the ceramic rollers are helpful in achieving these goals.KAMROLLER is a company that provides the highest quality ceramic roller, and excellent customer service, as well as technically knowledgeable personnel to ensure that you can find the right solution for your problem.

Read more: Remarkable Properties of Fused Quartz Powder