Quartz Ceramic Guide Groove

✦ Material characteristics: – High quality ceramic material – High hardness, wear resistance – High temperature resistance, corrosion resistance – Smooth surface

✦ Guide rail effect: – Excellent sliding performance – Low friction coefficient – Stable and durable performance – Reduce guide rail wear

✦ Advantages: – Extend product life – Improve operation accuracy and stability – Reduce maintenance costs – Improve overall machine reliability

✦ Application areas: – CNC machine tools – Industrial robots – Automation equipment – Precision instruments

Product Image

Product Certificate

-

DESCRIPTION

-

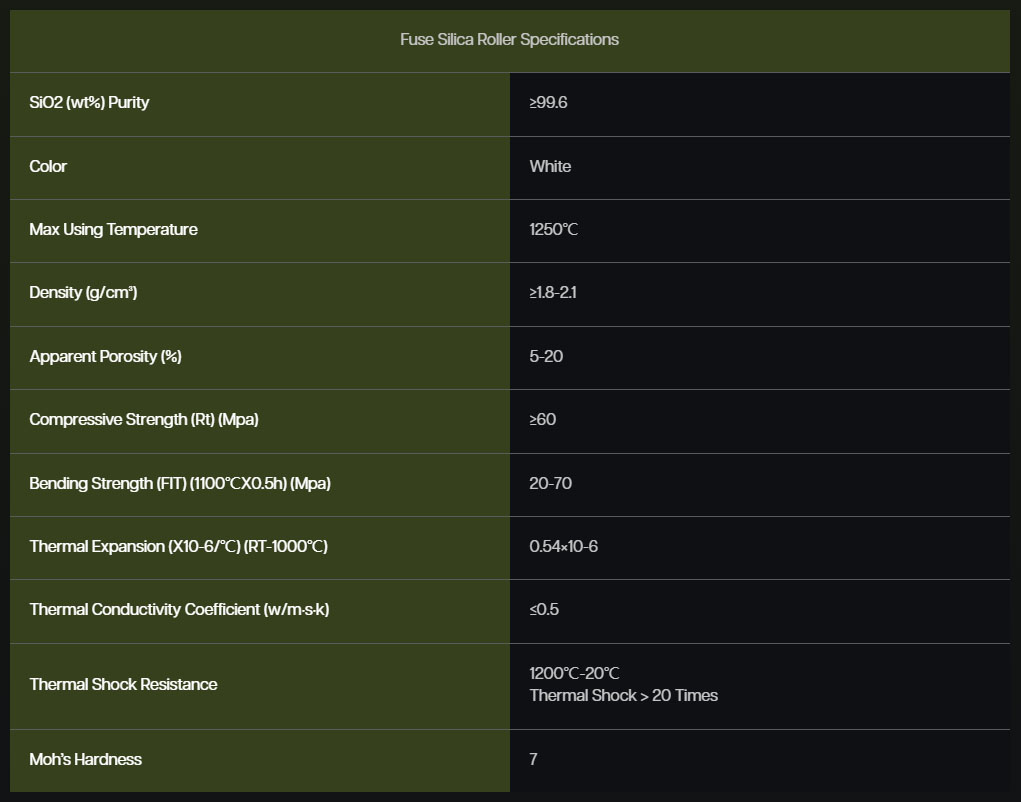

SPECIFICATION

-

FQA

The Quartz Ceramic Guide Groove represents a pinnacle of precision engineering, meticulously designed to meet the exacting demands of modern industries. This specialized component serves as a critical element in guiding applications, providing unparalleled accuracy and reliability in a wide range of settings. Crafted from high-quality quartz ceramic materials, the Quartz Ceramic Groove ensures exceptional durability, thermal stability, and precision, making it an indispensable asset in various industrial applications.

The Quartz Ceramic Guide Groove is the epitome of precision engineering, meticulously designed to provide unparalleled accuracy and reliability in guiding applications. Crafted from high-quality quartz ceramic materials, these guide grooves ensure exceptional durability and longevity even in the most demanding environments. With tight tolerances and precise machining, they guarantee smooth and precise movement, making them indispensable in critical guiding applications across various industries.

Key Features of Quartz Ceramic Guide Groove

High-Quality Materials: Crafted from premium quartz ceramic materials, the guide groove offers exceptional durability and reliability, ensuring long-lasting performance even in the most demanding environments.

Precision Machining: Each guide groove is meticulously machined to tight tolerances, guaranteeing smooth and precise movement for optimal performance in guiding applications.

Wärmestabilität: The quartz ceramic material provides outstanding thermal stability, allowing the guide groove to maintain its dimensional integrity and performance even under extreme temperature conditions.

Chemical Resistance: Quartz ceramic is highly resistant to a wide range of chemicals, ensuring the integrity of the guide groove in corrosive environments and protecting against degradation over time.

Low Friction: The smooth surface of the ceramic guide groove minimizes friction, reducing wear and tear and ensuring smooth and efficient operation over extended periods.

Applications of Quartz Ceramic Guide Groove

✦ The versatility and precision of the Quartz Guide Groove make it suitable for a variety of industrial applications, einschließlich:

✦ Precision Machinery: Used in precision machinery and equipment for guiding and positioning components with high accuracy and reliability.

✦ Semiconductor Manufacturing: Essential in semiconductor manufacturing equipment for guiding delicate components during the fabrication process.

✦ Medical Devices: Employed in medical devices and equipment for guiding and positioning surgical instruments and components with precision.

✦ Optical Systems: Utilized in optical systems and equipment for guiding and positioning lenses, Spiegel, and other optical components with exceptional accuracy.

✦ Aerospace Industry: Critical in aerospace applications for guiding and positioning components in aircraft, spacecraft, and satellite systems with precision and reliability.

Why Trust Kamrollers

Kamrollers has earned a reputation as a trusted leader in precision engineering, with a commitment to delivering high-quality products and exceptional customer service. Here’s why you can trust Kamroller for your Ceramic Guide Groove needs:

Expertise and Experience: With years of experience in precision machining and engineering, Kamroller has the knowledge and expertise to deliver superior products tailored to meet the unique needs of each customer.

Quality Assurance: Each Quartz Ceramic Groove undergoes rigorous quality control checks to ensure precision, reliability, and performance, meeting the highest industry standards.

Custom Solutions: Kamroller offers customized solutions to meet specific customer requirements, providing personalized service and expert guidance throughout the process.

Quartz ceramic guide slots are a crucial component used in electronic products. They are primarily employed to enhance the durability and reliability of the products. The notable features of quartz ceramic guide slots include:

1. High Temperature Resistance: Quartz ceramic materials can maintain their physical and chemical properties in high-temperature environments, making them suitable for electronic products that require high-temperature operations.

2. Corrosion Resistance: Quartz ceramics exhibit excellent resistance to various chemicals, allowing them to be used in corrosive environments without degradation, ensuring the stability and longevity of electronic components.

3. High Mechanical Strength: The high mechanical strength of quartz ceramics enables them to withstand significant mechanical stress and impact without breaking or deforming, ensuring the structural stability of electronic products during use.

4. Excellent Insulation Performance: Quartz ceramics possess superior electrical insulation properties, effectively preventing current leakage and protecting electronic components’ normal operation, ensuring the safety and reliability of the products.

What is a quartz ceramic guide groove?

A quartz ceramic guide groove is a precision-engineered component typically used in industrial and manufacturing processes. It is made from high-purity quartz ceramic material and is designed to guide and support various materials or tools within machinery.

What are the main applications of quartz ceramic guide grooves?

Quartz ceramic guide grooves are commonly used in industries such as semiconductor manufacturing, optical fiber production, high-temperature furnaces, and precision machining. They serve as guiding components in these high-precision and high-temperature environments.

What are the advantages of using quartz ceramic for guide grooves?

igh Purity: Quartz ceramic has minimal impurities, making it suitable for sensitive applications. Wärmestabilität: It can withstand high temperatures without degrading. Chemical Resistance: Quartz ceramic is resistant to most chemicals and corrosive environments. Mechanische Stärke: It offers high mechanical strength and durability. Niedrige thermische Expansion: This material has a low coefficient of thermal expansion, ensuring dimensional stability under temperature changes.

How is a quartz ceramic guide groove manufactured?

Quartz ceramic guide grooves are manufactured using processes such as precision machining, sintering, and polishing. These processes ensure the grooves meet the required specifications and tolerances for high-precision applications.

What are the key specifications to consider when selecting a quartz ceramic guide groove?

Dimensions: The length, width, and depth of the groove. Tolerance: The allowable deviation from specified dimensions. Surface Finish: The smoothness of the groove's surface. Material Grade: The purity and specific properties of the quartz ceramic used. Thermal and Chemical Compatibility: Suitability for the intended operating environment.

Can quartz ceramic guide grooves be customized?

Yes, quartz ceramic guide grooves can be customized to meet specific requirements. Customization options include specific dimensions, tolerances, surface finishes, and additional features such as holes or notches for mounting.

What are the maintenance requirements for quartz ceramic guide grooves?

Quartz ceramic guide grooves typically require minimal maintenance due to their durability and chemical resistance. Jedoch, regular inspections should be conducted to ensure they remain free of cracks, chips, or other damage that could affect performance.

How do quartz ceramic guide grooves compare to other materials like metal or plastic?

Wärmestabilität: Quartz ceramic is superior in high-temperature environments compared to plastic and many metals. Chemical Resistance: It offers better resistance to corrosive chemicals than most metals and plastics. Mechanische Stärke: Quartz ceramic provides higher strength and rigidity compared to plastic but is more brittle than some metals. Purity and Cleanliness: Quartz ceramic is preferred in ultra-clean environments, such as semiconductor manufacturing, where contamination is a concern.

Are there any limitations to using quartz ceramic guide grooves?

Brittleness: Quartz ceramic is more brittle and can crack or chip under impact or excessive force. Cost: It can be more expensive compared to other materials like metal or plastic. Customization Lead Time: Custom manufacturing of quartz ceramic components may have longer lead times due to the precision required.

Where can I purchase quartz ceramic guide grooves?

Quartz ceramic guide grooves can be purchased from specialized suppliers of industrial ceramics, semiconductor equipment manufacturers, and precision machining companies. It is essential to select a reputable supplier to ensure the quality and reliability of the product.