Fused Silica Plates

✦ Material properties: High purity – Low thermal expansion coefficient – Good optical properties – Strong chemical stability – Excellent thermal shock resistance

✦ Application areas: – Optical lenses – Semiconductor equipment – Experimental instruments – Laser processing – Vazduhoplovstvo

✦ Production advantages: – Advanced production technology – Strict quality control – Fast delivery cycle – Professional technical support – Customizable according to customer needs

✦ Cost-effectiveness advantage: – High performance-price ratio – Better than similar products – Competitive in the market

Product Image

Product Certificate

-

DESCRIPTION

-

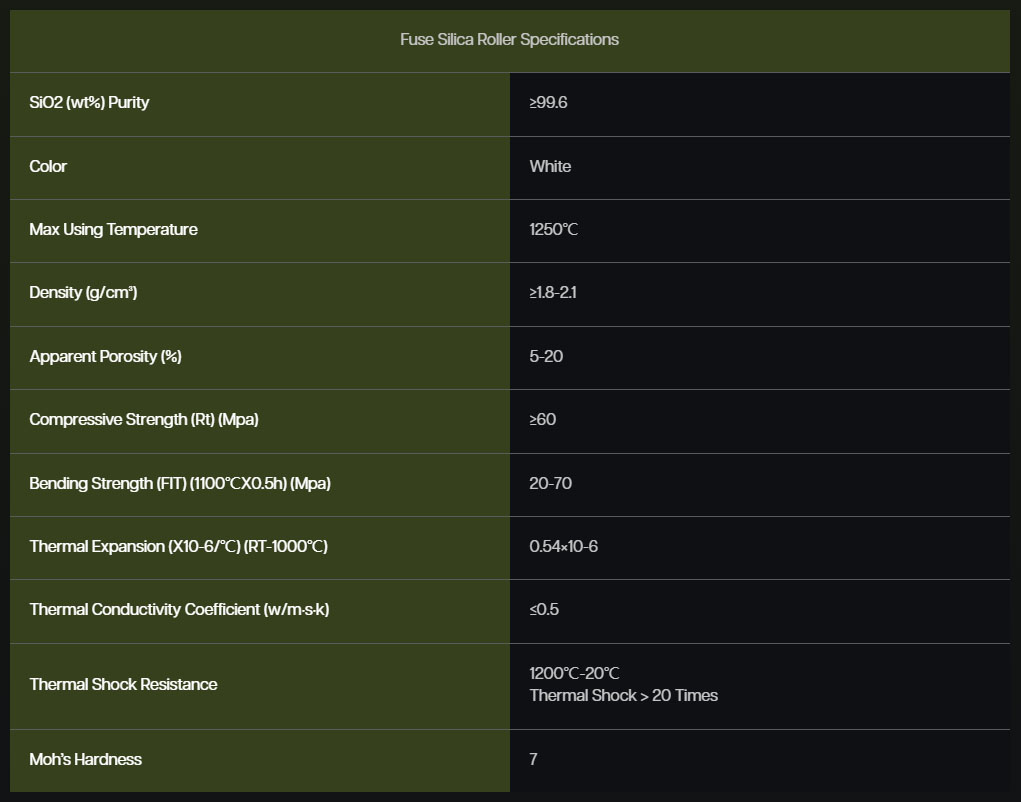

SPECIFICATION

-

FQA

Fused silica plates stand as the pinnacle of material engineering, meticulously crafted from high-purity silicon dioxide. Renowned for their exceptional thermal stability, chemical resistance, and precise dimensional control, these plates are indispensable across a spectrum of industries. Fused silica plates, manufactured to exacting standards, serve as critical components in applications where accuracy, durability, and reliability are paramount.

Investing in fused silica plate is a strategic decision that offers a multitude of benefits across various industries. With their unrivaled thermal stability, chemical resistance, and precision machining, fused silica plate ensure unparalleled performance and longevity in critical applications. Whether you’re operating in the semiconductor industry, where precise photomask fabrication is paramount, or navigating the complexities of optical systems requiring stable platforms for lenses and mirrors, fused silica plates deliver the reliability and accuracy needed to excel.

Features of Fused Silica Plates

High Purity: Crafted from 99.99% pure fused silica, these plates ensure minimal contamination and uphold the highest quality standards in industrial processes.

Thermal Stability: Fused silica’s remarkable ability to withstand extreme temperatures without distortion makes these plates ideal for applications requiring heat resistance and thermal uniformity.

Low Thermal Expansion: With a low coefficient of thermal expansion, fused silica plate maintain their dimensional stability even in the face of rapid temperature fluctuations, preventing warping or deformation.

Chemical Resistance: Fused silica’s innate resistance to a wide range of chemicals safeguards the integrity of the plates and ensures compatibility with corrosive environments, extending their lifespan and reliability.

Precision Machining: Fused silica plates are meticulously machined to exact specifications, guaranteeing tight tolerances and surface flatness essential for precision applications.

Applications of Fused Silica Plates

Semiconductor Industry: In semiconductor manufacturing, fused silica plates are utilized as precision substrates for photomask fabrication, ensuring optimal imaging performance and defect-free production.

Optical Systems: These plates serve as critical components in optical systems, providing stable platforms for lenses, mirrors, and other optical elements, thereby enhancing imaging quality and system performance.

Laser Technology: Fused plates are integral in laser systems, serving as beam splitters, windows, and substrates due to their exceptional optical clarity, thermal resistance, and durability.

Analytical Instruments: Fused plates find application in analytical instruments such as spectrometers and chromatographs, where their thermal stability and chemical resistance ensure accurate and reliable measurements.

High-Temperature Environments: Industries requiring materials capable of withstanding extreme temperatures, such as aerospace and automotive, rely on fused silica plates for their thermal stability and resilience in harsh conditions.

Why Trust Kamrollers

Kamrollers stands as a beacon of excellence in the realm of fused silica technology, committed to delivering products of uncompromising quality and performance. Here’s why you can trust Kamroller for your fused silica plate needs:

Expertise and Innovation: With decades of experience and a relentless pursuit of innovation, Kamrollers remains at the forefront of fused silica technology, continually pushing boundaries to meet evolving industry demands.

Osiguranje kvaliteta: Each fused silica plate undergoes rigorous quality control measures to ensure adherence to strict performance criteria, guaranteeing consistency and reliability in every product.

Customer-Centric Approach: Kamroller prioritizes customer satisfaction, offering personalized service and technical expertise to address unique requirements and challenges.

What is fused silica

Fused silica is a type of glass made from high-purity silica (SiO2). It has a non-crystalline structure, meaning it lacks the regular atomic arrangement found in most glasses.

What are fused silica plates used for?

Fused silica plates are used in various applications due to their exceptional optical properties, high thermal stability, and resistance to chemical attack. Common uses include optical components in lasers, lenses, windows, mirrors, semiconductor manufacturing, and scientific instruments.

What are the key properties of fused silica plates?

High Transparency: Excellent transmission in the ultraviolet (UV), visible, and infrared (IR) spectra. Low Thermal Expansion: Minimal dimensional changes with temperature variations, making them suitable for high-temperature applications. High Thermal Stability: Can withstand temperatures up to 1200°C. Chemical Resistance: Resistant to most acids and chemicals. High Purity: Contains very low levels of impurities, making it ideal for sensitive optical and scientific applications.

How are fused silica plates manufactured?

Fused silica plates are typically produced through the melting and cooling of high-purity silica. The process involves heating silica to its melting point and then cooling it rapidly to form a non-crystalline glass.

What are the differences between fused silica and quartz?

While both materials are composed of silica (SiO2), fused silica is an amorphous form of silica without a crystalline structure, whereas quartz is crystalline. Fused silica has superior optical properties and thermal stability compared to quartz.

What are the applications of fused silica plates in the semiconductor industry?

In the semiconductor industry, fused silica plates are used in photomask substrates, wafer carriers, and as components in photolithography systems due to their high purity, thermal stability, and excellent optical properties.

Can fused silica plates be customized?

Yes, fused silica plates can be customized in terms of size, thickness, surface finish, and coatings to meet specific application requirements. Custom shapes and dimensions are often produced for specialized uses.

What surface finishes are available for fused silica plates?

Common surface finishes for fused silica plates include polished, ground, and as-cut surfaces. Polished surfaces offer the highest optical clarity and smoothness, while ground and as-cut surfaces are used in less demanding applications.

Are fused silica plates resistant to radiation?

Yes, fused silica plates exhibit good resistance to radiation damage, making them suitable for use in environments with high levels of radiation, such as space and nuclear applications.

How should fused silica plates be handled and cleaned?

Fused silica plates should be handled with care to avoid scratches and contamination. Cleaning typically involves using mild solvents and non-abrasive materials. Avoid using strong acids or bases that could damage the surface.

What are the limitations of fused silica plates?

Fragility: Fused silica plates can be brittle and prone to cracking if not handled properly. Cost: The high purity and specialized manufacturing process can make fused silica plates more expensive than other glass materials.

How do I choose the right fused silica plate for my application?

Consider factors such as the required optical properties, thermal stability, chemical resistance, and mechanical strength. Consulting with a supplier or manufacturer can help determine the best specifications for your specific needs.