How to Maintain Fused Silica Ceramic Rolls for Optimal Performance?

2024.06.26администратор

Керамични ролки от стопен силициев диоксид: The Unbeatable Choice for High-Performance Applications

In the case of high temperatures and extreme industrial environments, traditional materials often fall short of the mark. Въпреки това, you should not worry because fused silica rolls are the new king. These wonderful components are made from high-purity fused silica and give a set of properties that make them ideal for use in a number of applications. Fused quartz is often called “fused silica ceramic rolls,” however this is a different material with particular characteristics. This paper aims at providing an insight into fused silica rolls including their properties, advantages over the traditional options, and their versatility in the various sectors.

Why Fused Silica Rolls Reign Supreme

Although conventional materials such as metal or ceramic rollers have been utilized by diverse sectors, fused silica presents unique benefits:

- Better Performance in High-Temperature Conditions:

During high temperatures, metal rollers are prone to wear out or they may even become weak. Fused silica will not change its properties and characteristics even if exposed to high temperatures when used in a process; this ensures that the process is as effective as intended.

- Unmatched Chemical Resistance:

Some of the chemicals may be too strong for the ceramic rollers commonly used in the beauty industry. Due to its high chemical stability, fused silica can be used in many chemical processing applications.

- Dimensional Stability for Accurate Control:

The temperature change might influence the accuracy of the metal rollers as they expand. For processes that require very accurate measurements, the use of fused silica rollers will be beneficial because they have minimal variation in dimensions.

Fused Silica Rolls: Perfect for High-Temperature Applications:

While fused silica ceramic rolls are widely used in the high-temperature applications that are commonly associated with furnaces, their history is not limited to this area. Because of the characteristics that make this material versatile, it is successful in numerous fields. Let’s investigate some surprising areas where fused silica rolls have taken over:

- Precision Manufacturing:

In high-precision manufacturing, it is important that the components to be produced shall have good dimensional stability. Lower thermal expansion results in the fact that fused silica rollers offer a precise and stable management of fragile items, including electronics or micromachining components.

- Chemical Processing Powerhouse:

Far more often conventional rollers are exposed to severe damage due to the action of aggressive chemicals. The exceptional chemical inertness of the fused silica, it makes it a very reliable material in conveying products or equipment parts through chemically hostile environments.

- The Hidden Hero of Semiconductor Manufacturing:

Така, the level of purity is very important during the process of manufacturing semiconductors. Due to their high surface quality and minimal chemical interaction fused silica rollers are used in generating a clean environment, which is crucial for sensitive semiconductor components.

Fused Silica Rolls: Unrivaled Capability, Safety First

For applications that require high working temperatures, fused silica rolls are unmatched. These attributes lead to excellent performance since they are associated with the benchmark of quality. Въпреки това, when working with fused silica rolls, safety is not an option while at the same time enjoying the advantage. What you should know is as follows:

- Risk of Crystalline Silica Dust:

During the machining of fused silica, crystalline silica dust which is hazardous to inhale is generated. Some of the measures that can be employed to enhance the safety of workers include proper dust control measures such as proper ventilation and respirators that meet the legal requirements of the area of operation for instance OSHA standards in America.

- Handle with Care:

Fragile Under Impact: Fused silica is brittle thus having a high thermal stability although it is naturally brittle. The following are some tips to help prevent breakage: when using it, handling it, keeping it, and putting it in place. It is suggested to use safe lifting techniques and one can also think about placing blankets or rugs on the ground to avoid getting chips or cracks.

- Reduce Thermal Shock:

Fused silica can break because of extreme and abrupt changes in temperature. Fused silica components should always be heated up and cooled down in a controlled manner and in equal rates. Така, the tension and the probability of material breaking are lowered when the material is heated slowly.

- Eye Protection is Essential:

This requires the wearing of eye protection because fragments of fused silica can cause severe eye injuries. It is recommended that when handling, machining, and installing fused silica rolls, safety glasses or a face shield must be worn.

Collaborating for a Secure and Effective Operation:

We at Kamroller are not only proud of providing the most high-quality fused silica ceramic rolls, but we also provide the information and equipment that would make your workplace safe. To get more information on how to handle, store, and dispose fused silica rolls safely, please refer to our safety information.

Така, you can use fused silica rolls to their entire potential while minimizing the risk and providing the best working conditions for your employees by adhering to safety measures and cooperating with a reliable supplier like Kamrollers.

Fused Silica Rolls: Maintaining Peak Performance for Long-Lasting Success

Flexible and bushed rolls made of fused silica have been established as the best performers in severe and high-temperature services. Despite that, proper care measures are necessary to ensure that the product has a long life expectancy and is efficient. Here’s how to maintain the best possible condition for your fused silica rolls:

- Frequent Inspections:

Schedule check-ups to identify areas of the floor that show signs of wear and tear such as chipping, cracking, or warping. The visual examination is one way of undertaking these checks but non-destructive examinations such as the ultrasonic examination offer a better assessment. This technique does not damage the roll and instead applies sound waves to detect imperfections on the inside.

- Cleaning is Essential:

Dust or debris may accumulate on the surface of the fused silica rolls as time passes by. To maintain and not damage the body surface, and to avoid premature fatigue, the surface should be cleaned regularly with a soft, lint-free cloth, and suitable cleaning agents; it is recommended not to use strong chemicals. If, however, the deposits are very stubborn, it is advised to consult your fused silica roll supplier for proper and safe methods of cleaning.

- Reduce Thermal Shock:

The mere fused silica which is known for its strength could also break due to temperature shocks. It is warned that fused silica rolls should always be heated and cooled slowly to avoid thermal stress. This helps in enhancing the life of your rolls by following a certain heating and cooling schedule.

- Appropriate Handling:

When working with, storing, or installing fused silica rolls it is recommended to take precautions. Avoid twisting or overexerting the back and do not hit or bump into objects during transport. To avoid scratches or chips, it is recommended to place items on soft surfaces.

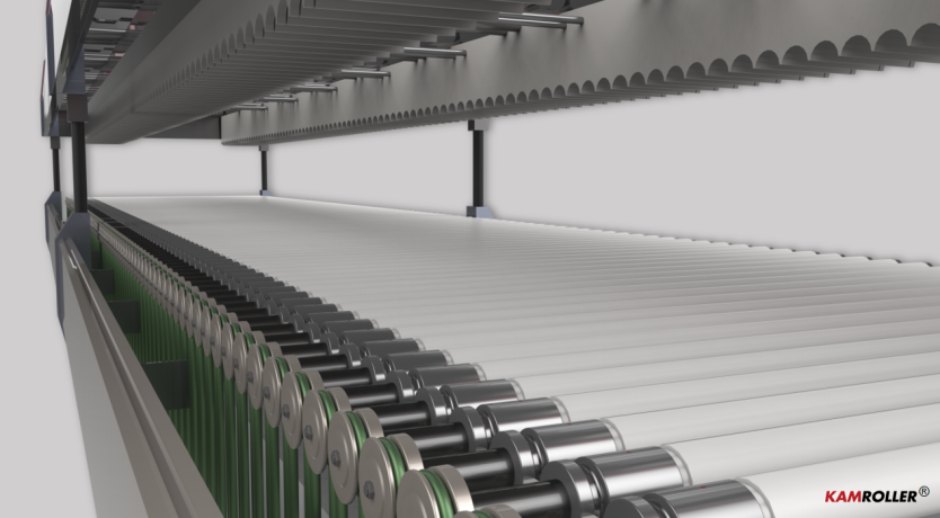

When Customization Matters: Why Kamrollers is Your Ideal Partner for Fused Silica Rolls

The fused silica ceramic rolls have also been critically tested and has been found to be very useful in high-temperature applications. But what if the need for a special touch is required because of your specific needs? All you have to do is visit Kamrollers, the only shop you will require for your fused silica rolls in specific dimensions.

Recognizing Your Needs:

All applications are not created in the same way. Kamrollers is fully conscious of the fact that your certain process may need certain sizes or structures of the fused silica rolls. Because of this, we offer a one-stop custom manufacturing service to suit your requirements as a client.

Accuracy and Proficiency:

We have a team of expert mechanics and technocrats with state-of-the-art tools and technology for fabrication. This allows us to produce the fused silica rolls with the set dimensions and specifications that you need. Quality is not compromised; every roll that is made is checked multiple times before it is shipped to you.

Beyond Personalization

It is not only centered on the provision of the fused silica rolls that are made to your specifications. We collaborate with you at every stage:

- Expert Consultation:

When it comes to your specific use, our specialists will provide you with recommendations concerning the types of materials, design aspects, and possible combinations.

- Quick Turnaround:

This is why we understand the financial consequences of disruption. We value our fast turnaround times as much as we value quality, that is why we never compromise on quality.

- Unmatched Quality:

For our custom rolls, we strictly ensure that we are using only the highest grade of fused silica. This makes it to have good chemical and thermal stability and also to have good dimensional stability for a long duration.

Why to Choose Kamroller?

- Customization Expertise:

We are well-equipped to manufacture fused silica rolls in the required size for the intended application.

- Unwavering Quality:

Beginning with the choice of material and ending with the final check of the product, all the stages are characterized by the remained allegiance to quality.

- Quick Turnaround Times:

We have the best production techniques to minimize your production time.

- Expert Support:

From the time a customer is in the process of making a purchase up to the point of after-sales service, our personnel are ready to assist.

Заключение:

Are you ready to discover how to get the best out of the fused silica ceramic rolls with specific dimensions? Do not delay to contact ГЪРБИЧНИ РОЛЕРИ now! For your efficiency, we will liaise with you to develop and supply the right fused silica rolls.

Прочетете повече: Fused Silica Crucible for Enhanced Purity & Performance