OUR SERVICES

36 Years Manufacturer, Unparalleled quality, enhance your experience through our Fused Silica Rollers services.

36 Years Manufacturer

Artisanal Fused Silica Rollers meticulously shaped and cured for unrivaled quality.

Customization service

Our Customization Service Delivers Exactly What You Need

Quality Assurance

Quality Assurance: Where Excellence Meets Expectations

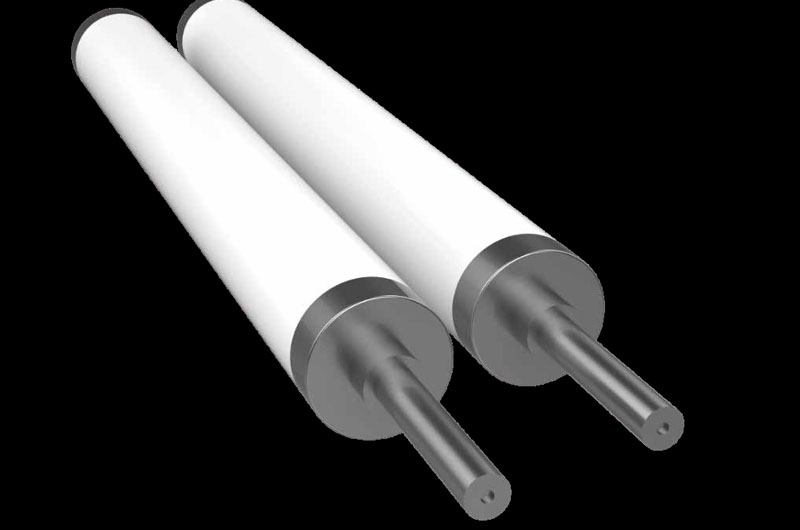

Fused Silica Rollers Details

Our products are primarily utilized in various industries including glass manufacturing, solar energy, aerospace, building ceramics, metal heat treatment, renewable energy, semiconductor, steel, petrochemical, and more.

North Glass Furnace Used Kamroller Fused Silica Rollers

Each Fused Silica Roller has been crafted from high-quality fused silica material, renowned for its outstanding thermal stability, low thermal expansion, and superior resistance to thermal shock. These properties make them ideal for withstanding the extreme temperatures and demanding conditions of glass production.

High Purity Fused Silica Raw Material

Quartz sand is used as a raw material and is converted into amorphous silica (fused silica) by high-temperature melting. Fused silica has a very low coefficient of thermal expansion and thermal conductivity, excellent thermal stability, and stable chemical properties.

Fused Silica Tweel

With superior grip, reduced maintenance, and enhanced comfort, the Fused Silica Tweel revolutionizes mobility and sets new standards for efficiency and reliability.

Fused Silica Ceramic Molds

In the glass industry, using quartz ceramics as a mold or carrier can effectively improve production efficiency, reduce the pollution of refractory materials to glass liquid, and improve product quality. Fused silica ceramic products have very good thermal shock resistance and can be directly replaced without preheating, greatly improving production efficiency. Quartz ceramic is made of 99.9% or more silica powder. It has the same chemical composition as glass; even if it is eroded, it will never cause secondary pollution.

ABOUT KAMROLLER

KAMROLLERS, founded in 1988, aims to be at the forefront of high-tech ceramics manufacturing, dedicated to delivering superior quality products and services globally. In 2006, Kamroller Special Ceramics Co., Ltd. was established, quickly rising to become Asia’s largest hub for high-end quartz products and their derivatives.

The company’s offerings are essential in various industries, including glass production, solar energy, aerospace, architectural ceramics, metal heat treatment, renewable energy resources, semiconductors, steel, petrochemicals, and more.

Watch Our Video Intro!

RECENT ARTICLES

Elevate Your Industrial Processes with Fused Silica Rollers: Precision, Durability, and Performance!

LET'S TALK TOGETHER

If you would like to know more about the products and services we provide, please contact us. Whether you need a standard solution or a tailored solution, we can provide you to meet your needs.